Fire Sprinkler systems for fires save lives. Standard spray sprinklers are used to put out fires by chilling and wetting surfaces to remove fuel sources and stop flashover, which is when everything in a room suddenly ignites when it reaches the autoignition temperature. This is furthered by some sprinkler types in particular systems, which are built to completely put out a fire in more difficult situations like storage facilities.

Question #1 – Recirculating Flowmeter with multiple Fire Pumps. Can a system utilizing multiple pumps have the discharge from the flowmeter recirculated to the fire pump(s) suction line?

In a system that has multiple fire pumps, a single flow meter connected to the water supply of the fire pumps can be used. NFPA 20, 2016 edition, Section 4.21.1.2 states that the outlet shall be utilized to test the pump and suction supply and ascertain that the system is working in accordance with the design when water consumption or discharge is prohibited for the period of the test indicated in Chapter 14. Diagrams for this configuration are provided in Section A.4.21.1.2 and Figure A.4.21.1.2(a). The image below shows three parallel fire pumps, one with a flow metre, and a bypass to the fire pump’s water supply.

Question #2 – Open Stairs not in Stairwells. In accordance with the 2016 edition of NFPA 13, is the stairway protection criteria found in section 8.15.3 applicable to open stairs that are not in a shaft?

The rules of Section 8.15.3, labelled “Stairways,” do not apply to stairways that are not enclosed in shafts. Instead, 8.5.5.3 and other general obstruction laws would be in effect. According to this rule, sprinklers must be put in under fixed objects with a width of more than 4 feet. Even though section 8.15.3’s title is just “Stairways,” this part also applies to steps that are contained in shafts. The sprinkler protection requirements for open stairs were the subject of a proposal by NFSA for the 2013 Edition of NFPA 13. In accordance to the explanation provided by the committee, open stairs are “addressed under the obstruction rules or as a continuation of the ceiling sprinkler spacing depending on configuration.” The request for permission was refused.

Question #3 – Clearance to Storage for ESFR Sprinklers beneath Wide Obstructions

A row of ESFR sprinklers beneath a duct exceeding 24 in. width is necessary per Section 8.12.5.3.1(1) of the 2013 edition of NFPA 13.

Is the 36 in. clearance-to-storage requirement in 8.12.6 applicable to the sprinklers beneath this obstruction provided the 36 in. clearance will be maintained from the ESFR sprinklers at the roof deck above?

Yes, sprinklers positioned below an obstacle must have a minimum of 36 in. of clearance from ESFR sprinklers to the top of storage. The clearance between the deflector and the top of storage must be 36 inches or more according to NFPA 13, 2013 edition, Section 8.12.6, and sprinklers that are beneath an obstacle are not exempt from this requirement. According to the handbook comments on this part, sprinklers erected according to the permitted spacing criteria cannot sufficiently overlap neighboring sprinkler discharge patterns with clearances less than 36 inches. The above-mentioned criteria for ESFR sprinklers are different from those for CMSA sprinklers that are allowed by Section 8.11.5.3.4 and Figure 8.11.5.3.4. The standard calls for a reduction in storage clearance for CMSA sprinklers that are beneath impediments, although it only applies to CMSA sprinklers and not to ESFR sprinklers.

Both Sections 14.2.12 for ESFR sprinklers and 13.2.8.3.4 for CMSA sprinklers in NFPA 13, 2022 edition, preserve these ideas.

Question #4 – Drum drips. Is there a specific frequency of when drum drips must be serviced or drained?

The frequency at which auxiliary drains should be drained is not regulated. The 2014 version of NFPA 25 says in Section 13.4.4.3.2 to discharge auxiliary drains after system operation, before and during freezing weather, and as necessary.

This is necessary since not all systems will contain the same quantity of water or condensation, necessitating case-by-case consideration. Additional details on how to choose an operating interval based on the discharge amount are provided in Annex Section A.13.4.4.3.2.

Question #5 - Low Pile Storage and Encapsulation. Does the fact that the commodity is encapsulated change the criteria of low-piled storage classification?

No, according to Table 4.3.1.7.1.1 Discharge criteria for miscellaneous storage up to 12 ft in height, Class III commodities stored on multiple row racks up to 12 ft would need to meet design criteria for OH2 (0.2 gpm/sq ft over 1500 sq ft).

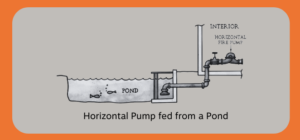

Question #6 – Horizontal Pump fed from a Pond. Is there a standard that describes specifics on how to feed a horizontal fire pump inside a building from a pond?

The installation requirement is NFPA 20, however unless the pump is at a lower elevation than the pond and the suction line is routed below grade and below the water level all the way to the pump suction, it is doubtful that a horizontal fire pump may be utilised when the water source is a pond. Water drafting or lifting is not authorised with horizontal fire pumps. Because of this, when the water source is a pond, only vertical turbine fire pumps are utilised.

It is necessary to continually prime horizontal split case fire pumps with a minimum suction pressure of 0 psi at 150 percent of the rated flow. The friction loss in the suction pipe between a suction tank and the pump suction flange can cause the suction for a horizontal split case pump to decrease to a minimum of -3 psi (at 150% flow).

It should be remembered that NFPA 20 formerly allowed horizontal fire pumps to function in a suction lift state. This exception was taken out of the 1974 edition of the standard and is no longer allowed.

Question #7 – Design Area Adjustments. s it possible to arrive at a design area of less than 2,000 square feet?

n Extra Hazard Group 2 dry pipe system will have K-11.2, high temperature rated sprinklers and is being installed in a building with a roof slope is less than 2/12. Per Section 19.3.3.2.8.1 of the 2019 edition of NFPA 13, multiple adjustments are compounded based on the area of operation originally selected from Figure 19.3.3.1.1.

Depending on the sequence of the adjustments, is it possible to arrive at a design area of less than 2,000 square feet?

No, as stated in Section 19.3.3.2.6, when installing high-temperature sprinklers in additional hazardous occupancies, the area of sprinkler operation can be decreased by 25% without changing the density, but never to less than 2,000 sq ft.

Additionally, in accordance with Section 19.3.3.2.7, the design area may be decreased by 25% when K-11.2 or bigger sprinklers are used with the additional hazard design curves, but never below 2,000 sq ft, irrespective of the temperature rating of the sprinklers employed.

Although it would be feasible, it is not allowed to arrive at a design area less than 2,000 square feet.

The changes can be made in any sequence, but the minimum 3,000 square feet requirement for areas with sprinklered combustible hidden spaces (where applicable) must be applied last.

Question #8 – Full Flow Trip Test of a Preaction System. Is a full flow trip of a preaction system required every three years and if so, how is it performed?

Yes, the preaction system must run completely every three years. The type of system, such as a single or double interlock system, will determine how the test operates.

Trip testing these systems involves a number of procedures. The NFPA 25 2020 handbook edition’s testing methods include a step-by-step order.

In other words, run the releasing system for a single interlock full flow test, and if electronically released, let the system pressure stabilise before closing the control valve and drain system.

The system would be tripped by withdrawing the supervisory pressure from the system if the system had a pilot line. It is necessary to keep track of both the supervisory air tripping pressure and the water to inspector’s test pressure in a double interlock system. In this kind of system, the electronic release must be turned on first to make sure the solenoid has turned on. The test connection for the inspector is then established. Take note of the valve’s trip time, trip pressure, and the duration of steady water flow at the test connection (similar to a dry pipe system test).

Question #9 – NFPA 14 - Design Basis based on 1978 Edition

The underground pipe for an existing dry manual standpipe and by doing so added 100 ft of additional pipe to the system. The AHJ wants a hydraulic calculation performed but the original hydraulic calculations have been lost or were never performed.

The AHJ will accept a new hydraulic calculation using the NFPA 14 design requirements from the era of the original design. The building was built in 1995 so it is believed the 1978 Edition NFPA 14 applies, please advise if a more recent NFPA 14 existed prior to the 1996 Edition.

The interpretation from the 1978 edition is that the standpipe system requires 500 gpm from a single standpipe at 65 psi.

Class I and Class III standpipes were to be designed for a minimum flow of 500 gpm in situations where a single standpipe was required, according to NFPA 14 Standpipe and Hose System, 1978 edition, Section 2-1.2. Where there were several standpipes, a minimum flow rate of 500 gpm was needed for the first standpipe and an additional 250 gpm for each succeeding standpipe, with a total flow rate of 2500 gpm being the maximum (section 5-3.1).

The 1980, 1983, and 1987 versions all included the same qualifications.

The highest outlet pressure requirement was increased to 65 psi in Section 2-1.2 of the 1990 edition, and the flow and pressure specifications remained constant until the 1993 edition.

Due to suggestions made during the One Meridian Plaza Fire in Philadelphia in 1991, which claimed the lives of three firemen, the 1993 version was altered. This version changed the flow requirements to 500 gpm for the first standpipe and 250 gpm for each succeeding standpipe, with a maximum flow of 1250 gpm, and increased the minimum hose outlet pressure requirements to 100 psi.

I would suggest it is appropriate to apply the 1993 edition to a structure erected in 1995, given it was the final version released before the building was constructed, assuming you are unable to verify the accepted standard that was utilised in the original design. For a Class I dry manual standpipe, this would call for a minimum pressure of 100 psi and flows of 500 gpm for the first standpipe and 250 gpm for each succeeding standpipe, with a maximum flow of 1250 gpm.

Question #10 – Wet Manual Standpipe Calculations requiring more than 150 psi at FDC

Section 6.4.5.2.2.1 of the 2019 edition of NFPA 14 states that the pressure required sign is not required when the pressure required is 150 psi or less.

I do not believe it is the intent to limit the pressure to 150 psi; however, I am having trouble finding code references to support the use of pressure over 150 psi.

You’re right; NFPA 14 does not restrict fire department connections to 150 psi. NFPA 14 Standard for the Installation of Standpipe and Hose Connection (2019), Section 6.4.5.2.2.1, states that a fire department connection (FDC) must have signs only when pressures are more than 150 psi. Pressurising FDCs to at least 150 psi pressure is advised as “common” practise. NFPA 13E, the Recommended Practise for Fire Department Operations in Properties Protected by Fire Sprinkler and Standpipe System, has this suggestion. Additionally, according to NFPA 13E, pump discharge pressures shouldn’t be greater than 200 psi unless the system is configured for a higher pressure and so is noted on the sign at the FDC.

The maximum pump pressure for a fire department is typically 250 psi, however pumping capability varies by county and should be confirmed with the local fire authority. The NFPA 1901 Standard for Automotive Fire Apparatus contains those specifications.

All standpipe system components must be rated for the pressure stated and fall within the maximum permissible pressure range.

Note that Section 6.4.5.2 also requires all manual standpipes to indicate whether the system is wet or dry.

Question #11 – Ceiling Pockets and Concrete Tee Construction. Do structural bays need to be protected as ceiling pockets in accordance with Section 8.8.7 of the 2016 edition of NFPA 13?

In a parking garage design extended coverage sprinklers are to be used. The construction of the parking garage consists of concrete double tees spaced approximately 4 ft-6 in apart.

Based upon the preliminary layout, their will be 2-3 structural bays between branch lines. It is being question if these structural bays are considered ceiling pockets.

Do structural bays need to be protected as ceiling pockets in accordance with Section 8.8.7 of the 2016 edition of NFPA 13?

The areas between the concrete tees aren’t regarded as ceiling pockets. It is not the intention of the ceiling pocket definition to apply to structural and/or frame members that are otherwise utilised to define obstructed or unobstructed construction, as indicated in Annex section A.3.3.4.

Sprinklers may be spaced without taking into account the ceiling pocket regulations outlined in Section 8.8.7 as long as the deflector position complies with the building arrangement criteria of Section 8.8.4.1.

Question #12 – What is the difference between fire-retardant materials and fire-resistant materials?

The terms “fire-resistant materials” and “fire-retardant materials” are defined and explained in NFPA 701 and 703. For instance, NFPA 703, 2021 edition, Section 3.3.1 defines a fire-retardant coating as one that, when tested in accordance with a test for assessing surface burning characteristics, decreases the flame spread index of Douglas fir or of any other tested combustible surface to which it is applied. Fire-retardant-treated wood is defined in Section 3.3.2 as wood that has been chemically impregnated during manufacturing using a pressure process or another method in order to display reduced surface-burning characteristics and prevent the spread of fire.

Sprinklers are not required according to the 2016 edition of NFPA 13, Section 8.15.7.2, if exterior canopies, roofs, porte-cocheres, balconies, decks, and similar projections are made of NFPA 703-defined noncombustible, limited-combustible, or fire retardant-treated wood, or if the projections are made of inherently flame-resistant noncombustible frame or wood.

Courtesy: Roland ASP, CET NFSA Technotes (Best of Feb 2022)