Rotaflow Fire Sprinkler & Standpipe Systems

Reliable Protection & Compliance!

Rotaflow specializes in top-tier fire sprinkler and standpipe systems—design, installation, and maintenance for ultimate safety. From commercial buildings to high-rise complexes, we ensure compliance and reliable fire protection.

A fire sprinkler system detects heat and automatically suppresses fires, minimizing damage and enhancing safety. Standpipe systems provide firefighters with immediate water access, ensuring rapid response in high-rise buildings and large facilities. Trust Rotaflow for expert fire protection

A fire sprinkler system, whether residential or commercial, should only be installed by a business accredited by a respected organization, such as a CASA member.

Fire Sprinkler Systems :

A fire sprinkler system is an important component of any fire protection strategy. These systems automatically detect heat and discharge water to suppress fires, preventing them from spreading. Automatic fire sprinkler systems significantly reduce fire damage and improve occupant safety.

Types of Fire Sprinkler Systems

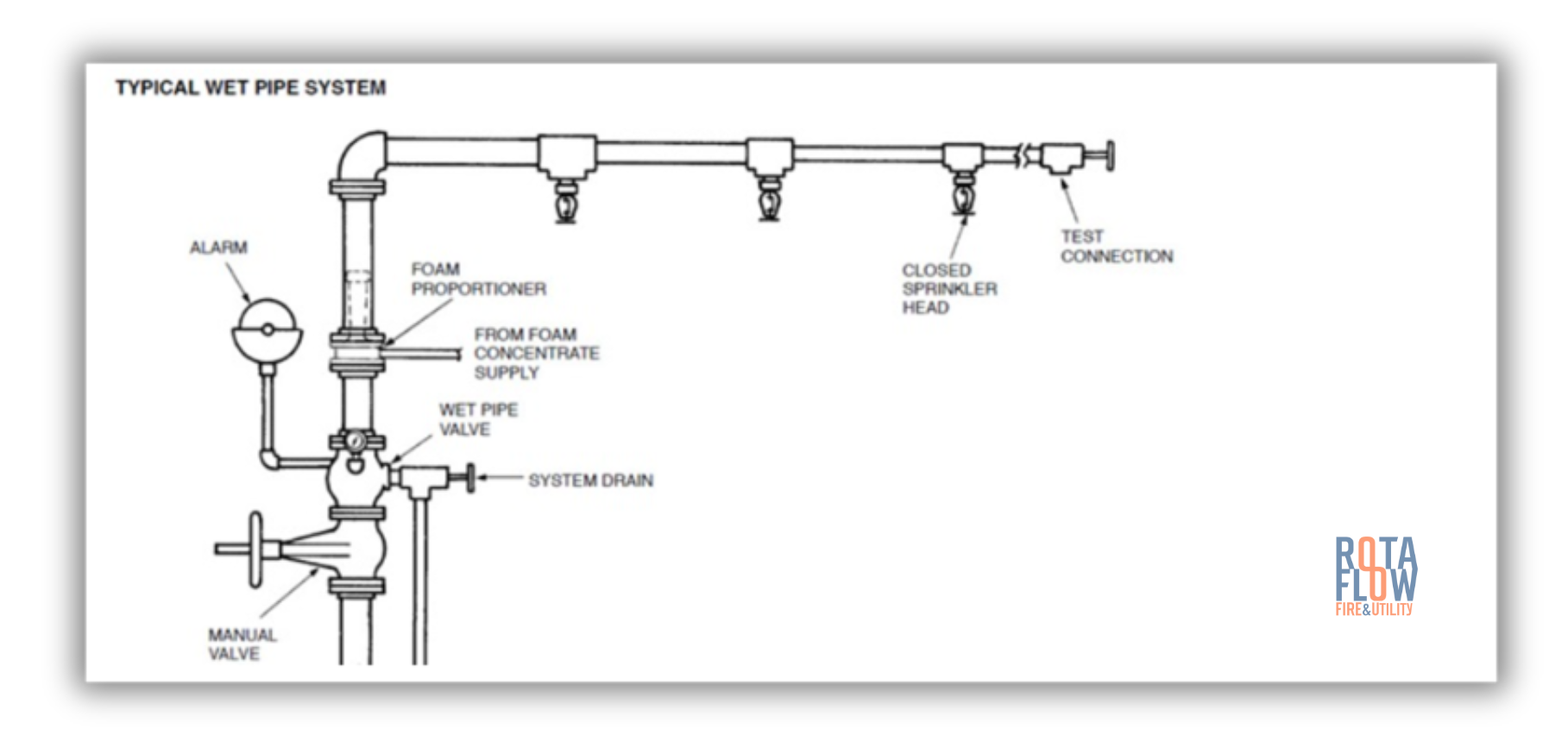

Wet Pipe Sprinkler Systems

The wet pipe fire sprinkler system is the most used type. It consists of pipes filled with water, which is immediately released when a sprinkler head is activated. These systems are ideal for commercial buildings, offices, and hotels.

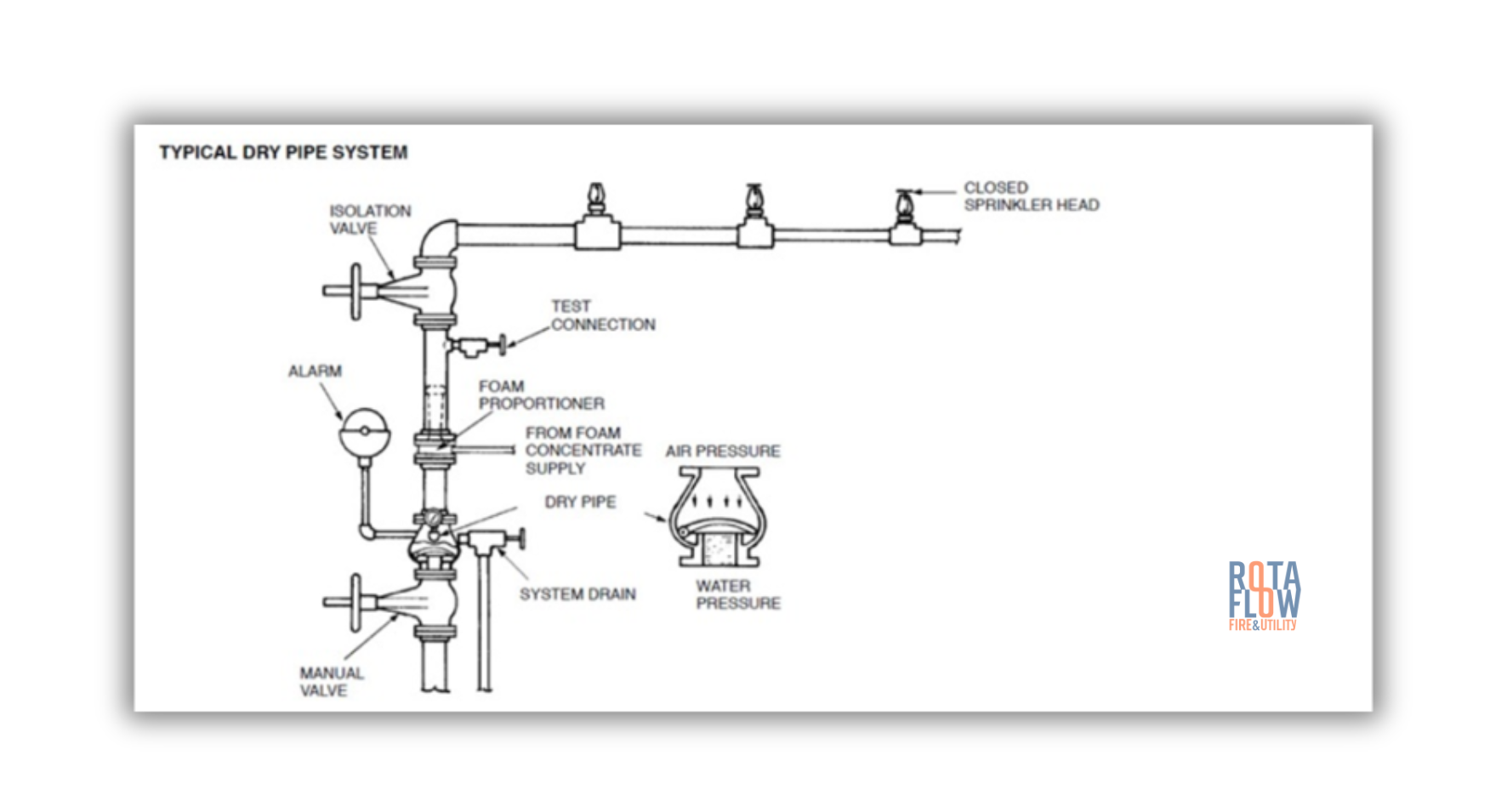

Dry Pipe Sprinkler Systems

A dry pipe sprinkler system is designed for environments where freezing temperatures could cause pipes to burst. Instead of water, the pipes are filled with pressurized air or nitrogen, which is released before the water flows through the pipes. This system is commonly used in unheated warehouses, parking garages, and industrial facilities.

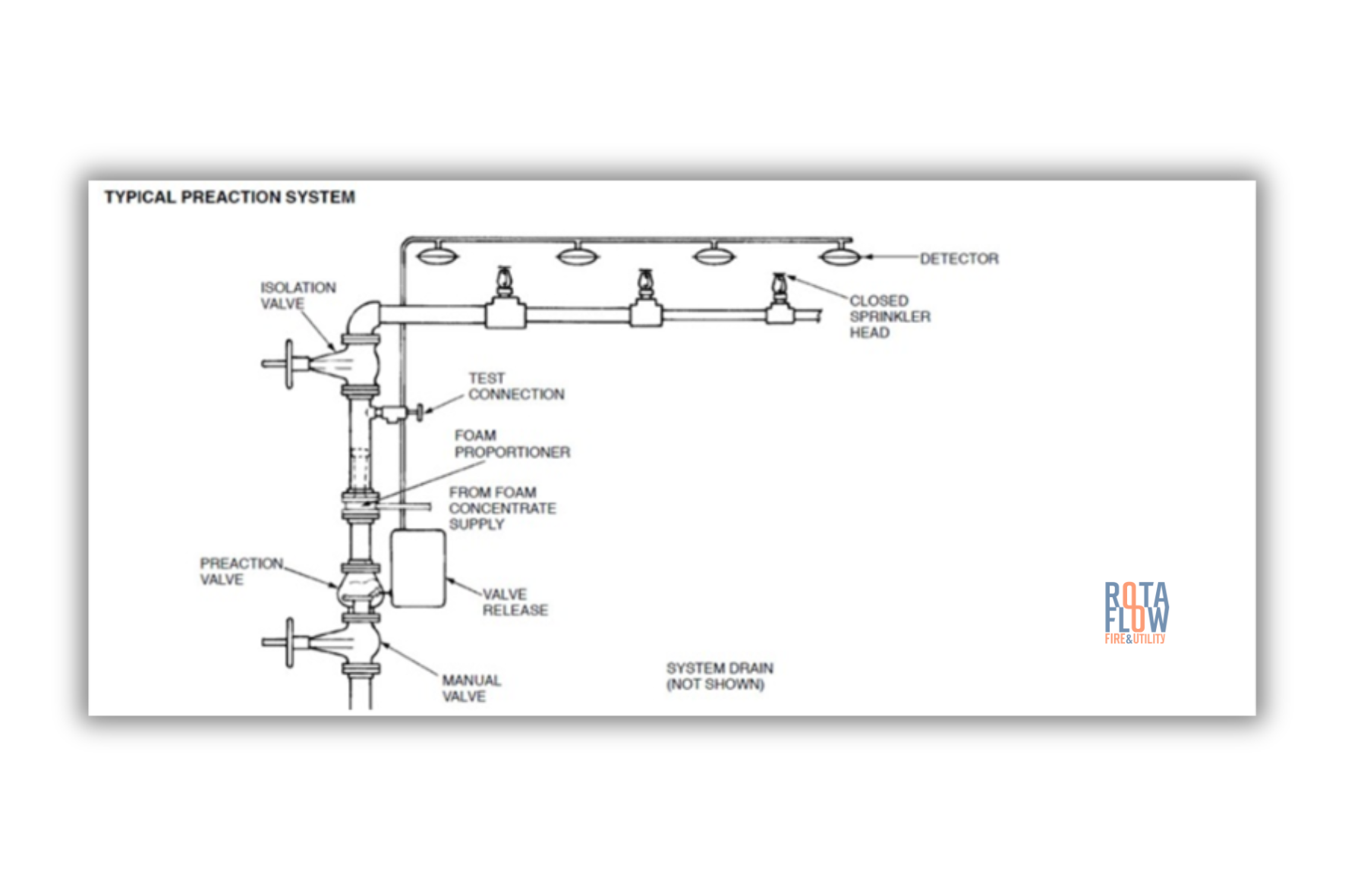

Pre-Action Sprinkler Systems

Pre-action systems require two activation steps, making them ideal for environments with sensitive equipment such as data centres, museums, and libraries. This type of fire suppression system prevents accidental water discharge.

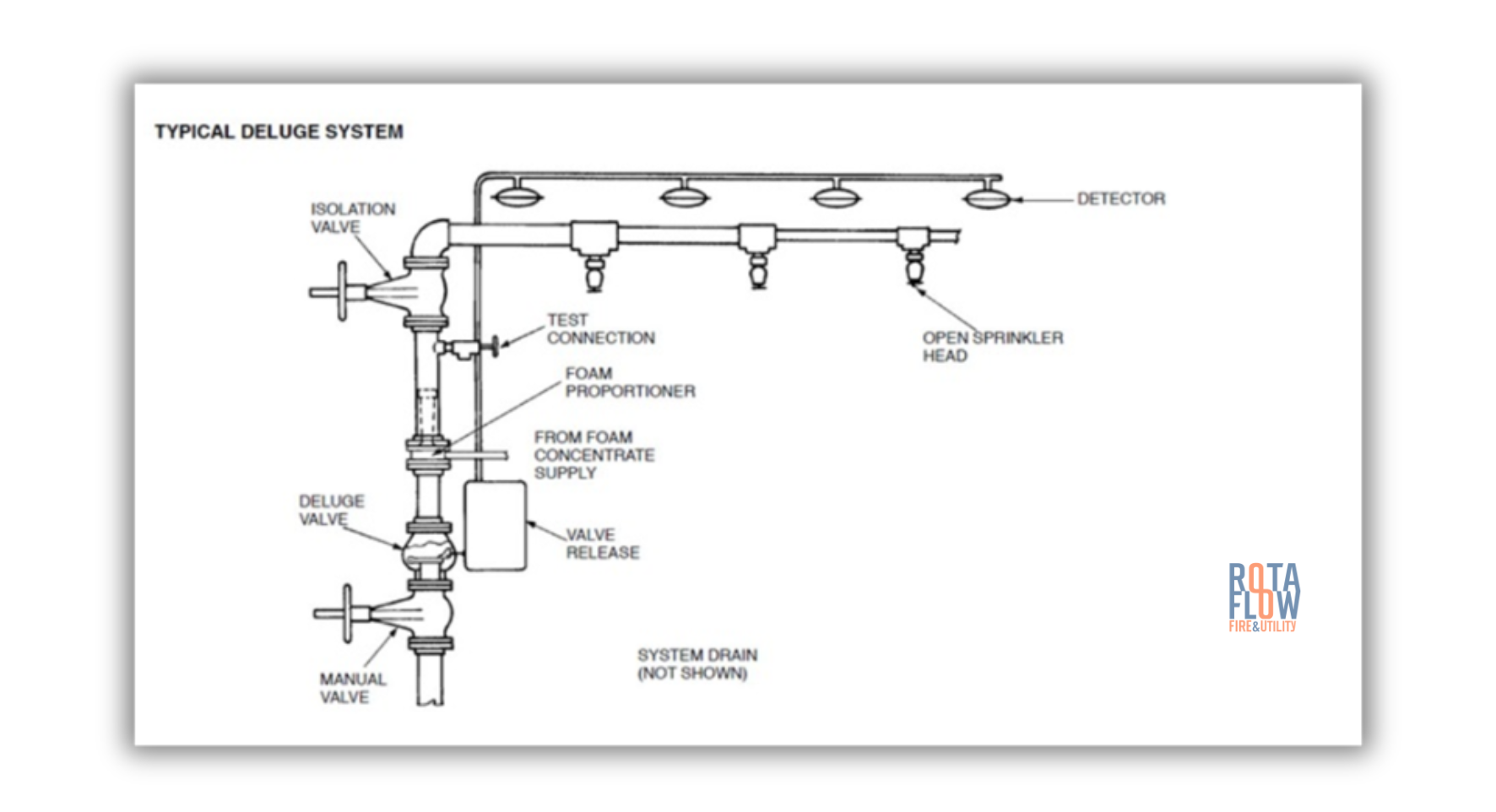

Deluge Sprinkler Systems

A deluge sprinkler system is used in high-hazard areas like chemical plants and power stations, where fires can spread rapidly. Unlike standard automatic fire sprinkler systems, all sprinkler heads in a deluge system activate simultaneously to flood the area with water.

Fire Standpipe Systems :

A standpipe system is a network of pipes that delivers water to multiple levels of a building, ensuring that firefighters have immediate access to water during an emergency. It serves as a fire department connection, allowing quick response times in high-rise buildings, warehouses, and large commercial properties.

Types of Fire Standpipe Systems

Class I Standpipe Systems

Equipped with 2.5-inch hose connections

Designed for use by trained firefighters

Common in shopping malls, stadiums, and high-rise office buildings

Class II Standpipe Systems

Features 1.5-inch hoses for use by trained building occupants

Found in hotels, hospitals, and educational institutions

.

Class III Standpipe Systems

A combination of Class I and Class II

Allows both firefighters and trained occupants to use the system

Installed in large industrial facilities and multi-story commercial buildings

Types of Fire Standpipe Systems Based on Water Supply

Automatic Wet Standpipe System

Water is constantly available in the pipes, allowing immediate use during a fire.

Automatic Dry Standpipe System

Pipes are filled with pressurized air, with water released upon activation

Manual Wet Standpipe System

Water is present in the pipes, but it relies on the fire department connection to maintain pressure.

Manual Dry Standpipe System

Pipes remain empty until the fire department pumps water into the system.

Rotaflow Annual Fire System Inspections

Ensure safety & compliance with Rotaflow’s annual fire system inspections! We cover sprinklers, standpipes, fire pumps, and alarms for optimal protection.

Contact us today!

Fire Sprinkler and Standpipe System Installation and Maintenance

At Rotaflow, we provide complete services, including:

1. System Design and Engineering

Our experts assess your building’s layout and fire risks to design a customised fire suppression system that meets NFPA (National Fire Protection Association) standards.

2. Professional Installation

We ensure that all components of your fire sprinkler and standpipe system are correctly installed, integrated, and fully operational.

3. Inspection and Testing

Routine fire sprinkler system inspections and standpipe system tests are necessary to ensure compliance with fire codes. Our services include:

● Fire system inspections to check for leaks, corrosion, and blockages

● Water flow tests to verify proper operation

● Pressure testing for standpipe systems

4. Regular Maintenance and Repairs

Proper maintenance ensures that your fire suppression system is always in peak condition. We provide:

● Emergency sprinkler system repairs

● Standpipe system flushing

● Fire safety compliance updates

5. 24/7 Emergency Support

We offer round-the-clock emergency support for unexpected system failures, ensuring your property is always protected.

Get a Free Consultation Today!

Protect your property with a reliable fire sprinkler system and standpipe system from Rotaflow. Contact us today for a consultation, inspection, or system upgrade.

Contact Us

Please note that all forms and emails will be replied to within 24 hours. For immediate assistance, call 780-469-1220.

Frequently Asked Questions (FAQs)

1. What is the difference between a fire sprinkler system and a standpipe system?

A fire sprinkler system is an automatic fire suppression system that detects heat and releases water to extinguish fires. In contrast, a standpipe system is a network of pipes that delivers water to multiple floors of a building, allowing firefighters to connect hoses and quickly access water during emergencies.

2. How often should fire sprinkler and standpipe systems be inspected?

According to NFPA standards, fire sprinkler and standpipe systems should be inspected annually. However, some components, such as valves and pressure gauges, require monthly or quarterly inspections.

3. Do all sprinkler heads activate when there’s a fire?

No. In wet, dry, and pre-action sprinkler systems, only the sprinkler heads closest to the fire activate. However, in deluge sprinkler systems, all sprinkler heads open at once to quickly control fires in hazardous areas.

4. Are fire sprinkler and standpipe systems required by law?

Yes, fire codes and building regulations often require fire sprinkler and standpipe systems in commercial, industrial, and high-rise buildings. The requirements vary based on local fire codes, NFPA standards, and insurance policies.

5. How can I maintain my fire protection system?

Regular inspection, testing, and maintenance ensure your system functions properly. At Rotaflow Fire & Utility, we provide:

- Routine fire sprinkler system inspections

- Standpipe system flushing and pressure testing

- Emergency repairs and system upgrades