Summary:

The National Fire Protection Association (NFPA) establishes very detailed rules and guidelines for fire protectionsystems. These codes are very helpful for designing, installing, inspecting, and maintaining systems, but people who work in the field often have to deal with real-world problems that aren’t always easy to solve. This is especially true when working with unusual site conditions, equipment setups, or code language that can change between editions.

This Journals answers some of the most prevalent technical questions about NFPA 13, NFPA 20, NFPA 22, NFPA 25, and NFPA 14. These questions are about real-life problems with fire protection, like whether a 100,000-gallon fire water tank can be put inside the building it protects, how chlorine disinfection affects sprinkler piping, whether braces under ESFR sprinklers count as obstacles, and how to understand travel distance rules for hose valves. Other subjects include how to protect sprinklers in freezers from “harsh environments,” how much space there needs to be between control valves, how to properly hold branchlines in place using hanger rods, and if electrical cables can be run on sprinkler pipes.

Each FAQ makes things clearer by pointing to the right NFPA sections and describing what the standard is meant to do. This Technote tries to close the gap between coding requirements and real-world use by breaking down these problems. The goal is to help engineers, contractors, inspectors, and facility managers better grasp what it means to be compliant without making mistakes that cost a lot of money or having to change the system unnecessarily.

These tips can help you make sure that your system is both code-compliant and reliable, whether you are managing a retrofit in an older structure, designing a fire suppression system for a new building, or answering questions during inspection and testing.

Question #1 – Tank Location

This inquiry asks whether a 100,000-gallon water storage tank (usually used for fire protection systems) can be installed within the same building it is supposed to protect. Concerns arise because such huge tanks necessitate a significant amount of space, structural support, and meticulous adherence to safety codes (such as NFPA 22). Installing it inside a protected building may offer concerns if the structure fails during a fire, hence codes frequently encourage or require separate, dedicated rooms or outdoor installation.

Question 1. Can a 100,000-gallon tank be installed within the building it protects?

Ans. NFPA 22 allows for the placement of a water storage tank inside the building it protects. However, there are crucial considerations for exposure prevention and water supply reliability.

According to the guidelines, NFPA 22 stipulates that a tank be secured from exposure fires.

See Section 4.3 of the 2023 edition of NFPA 22.

According to NFPA 22, tanks must be positioned at least 20 feet away from combustible structures or within 20 feet of one.

Fireproofed (sprayed with a protective coating) or protected by an exposure protection system.

There is no requirement to keep the tank away from non-combustible structures, and there is no special recognition for completely sprinklered structures. The standard does not mandate a minimum distance for tanks inside non-combustible or completely sprinklered buildings. However, the tank must still be protected from potential fires.

Question #2 – Chlorination

The project specifies disinfecting system components, such as the fire pump, piping, and equipment, with hypochlorites or liquid chlorine at a concentration of 50 ppm.

Question 2. Please provide guidance on the NFSA’s official position on chlorine-based disinfection of fire sprinkler piping and components, as well as any related literature or resources.

Ans. The NFSA does not advocate disinfecting sprinkler system pipework using chlorine. NFPA 13 and NFPA 20 do not provide guidelines on this approach, and there is no specialised literature on the subject.

Chlorine is commonly used to disinfect potable water, but its usage in fire sprinkler systems requires careful study. When using bacterial inhibitors to treat water supplies, it’s important to evaluate their efficiency beyond only preventing microorganisms.

Consider the influence on system components such pipes, fittings, sprinklers, gaskets, valves, and seals.

The chlorine levels used for disinfection are substantially higher than the concentrations found in typical city water. This can result in a variety of negative consequences, such as:

- Damage to pump packing, metallic components, and sprinkler system parts.

- Deterioration of rubber gaskets and closures.

- Enhanced expenses for system maintenance.

- Sprinklers may fail to activate during a fire due to potential operational failures, such as corroding and stuck-closed sprinkler seats.

Chlorine and other bacterial inhibitors can disinfect sprinkler piping, but their long-term effectiveness is unknown. Long-term studies are necessary to mitigate the danger of accelerated corrosion and system breakdown.

Section 14.1 of the NFPA 20, 2019 version specifies acceptance testing standards. Flushing is the recommended method for cleaning fire pump pipes, rather than chemical disinfection.

Question #3 – ESFR Obstruction

An ‘X’ is formed between four columns in an existing structure by a 6-inch-wide steel brace that runs diagonally from column to column. The buttress is situated at a minimum of 48 inches below the ESFR sprinkler deflectors.

Question 3. Is this brace an obstruction to the sprinkler discharge pattern?

Ans. No. In this situation, the steel bracing is 6 inches broad and 48 inches below the ESR deflector. The bracing meets the obstruction exception in NFPA 13, Section 8.12.5.3(3), which states that additional sprinklers are not required if the obstruction is less than 12 inches wide and at least 12 inches horizontally from the sprinkler.

The bracing is not considered an impediment, thus no additional sprinklers are needed below it.

Question #4 – NFPA 25 Harsh Environments

This question concerns if freezers and coolers are “harsh environments” according to NFPA 25, which says that sprinklers need to be tested more often in these kinds of places. The annexe comments clearly includes outside areas, however it doesn’t say anything about cold storage areas. The question is whether very low temperatures, such those in freezers, provide the same dangers (like corrosion or ice obstruction) that would make shorter testing periods necessary.

Question 4. NFPA 25 recommends shorter testing intervals for sprinklers in “harsh environments,” but does this also apply to freezers and coolers? The annexe commentary cites “outdoor environments” but does not provide examples for chilly temperatures.

Ans. Sprinklers must be tested or changed every five years, according to Section 5.3.1.1.2 of NFPA 25 (2023 edition).

The 2020 edition includes Section 5.3.1.1.3, which allows sprinklers with corrosion-resistant coatings to be tested or changed every 10 years.

Freezers and coolers aren’t typically considered tough environments. The term “outdoor environments” refers to situations that can accelerate corrosion, such as salt air, excessive humidity, or direct exposure to weather (snow, sleet, rain). Cold temperatures do not often increase rusting. If sprinklers in cold environments, such as freezers, exhibit corrosion earlier than predicted, it is recommended to test them and examine the source.

Question #5 Protection of Piping in Noncombustible Concealed Space

This inquiry is about whether the pipes that bring water to the fire sprinkler system can go through a crawlspace that doesn’t have sprinklers and is only accessible through a 36″ x 36″ opening. The worry is whether the crawlspace’s limited access and lack of sprinklers meet NFPA standards for installation, inspection, and maintenance.

Question 5. Can fire sprinkler lead-in mains be installed in unsprinklered, noncombustable crawlspaces with only a 36″ x 36″ hatch for access?

Ans. Yes. Sprinkler piping can be put in noncombustible concealed places, even without automatic sprinklers.

According to NFPA 13, 2013 edition, Section 8.16.4.3, private service main aboveground piping must be protected from mechanical and fire damage and not travel through hazardous regions. Private service main aboveground piping can be located in dangerous places with an automatic sprinkler system to ensure safety.

According to Section 3.8.1.11, a private fire service main refers to piping and associated equipment on private property.

- Connects a water source to the system riser in water-based fire protection systems.

- Connects a water source to inlets for foam-making systems.

- Connects a water supply with the base elbow of private hydrants or monitor nozzles.

- Used for fire pump suction and discharge.

- Starts at the intake side of a check valve on a gravity or pressure tank (NFPA 24).

According to Annex Section A.8.16.4.3, protection should be given in areas of a building with a higher level of hazard than the general occupancy.

Examples include locations with combustible or flammable materials, toxic or corrosive compounds, and heat-producing appliances.

Private fire service mains are usually built underground. Underground to aboveground transitions require protection. Aboveground private mains comprise tunnels and the first portion of piping entering a structure. Section 16.4.3.2 specifies that plumbing should be buried outside, but routing within a building may be appropriate in certain instances. Piping should not be exposed to hazardous regions that could cause damage and disrupt water supply to other parts of the system. Automatic sprinklers built for a specific hazard reduce the likelihood of main damage.

The noncombustible concealed space is not considered a hazardous area that requires sprinkler protection for the piping. Additionally, no private fire service main piping is built within the space.

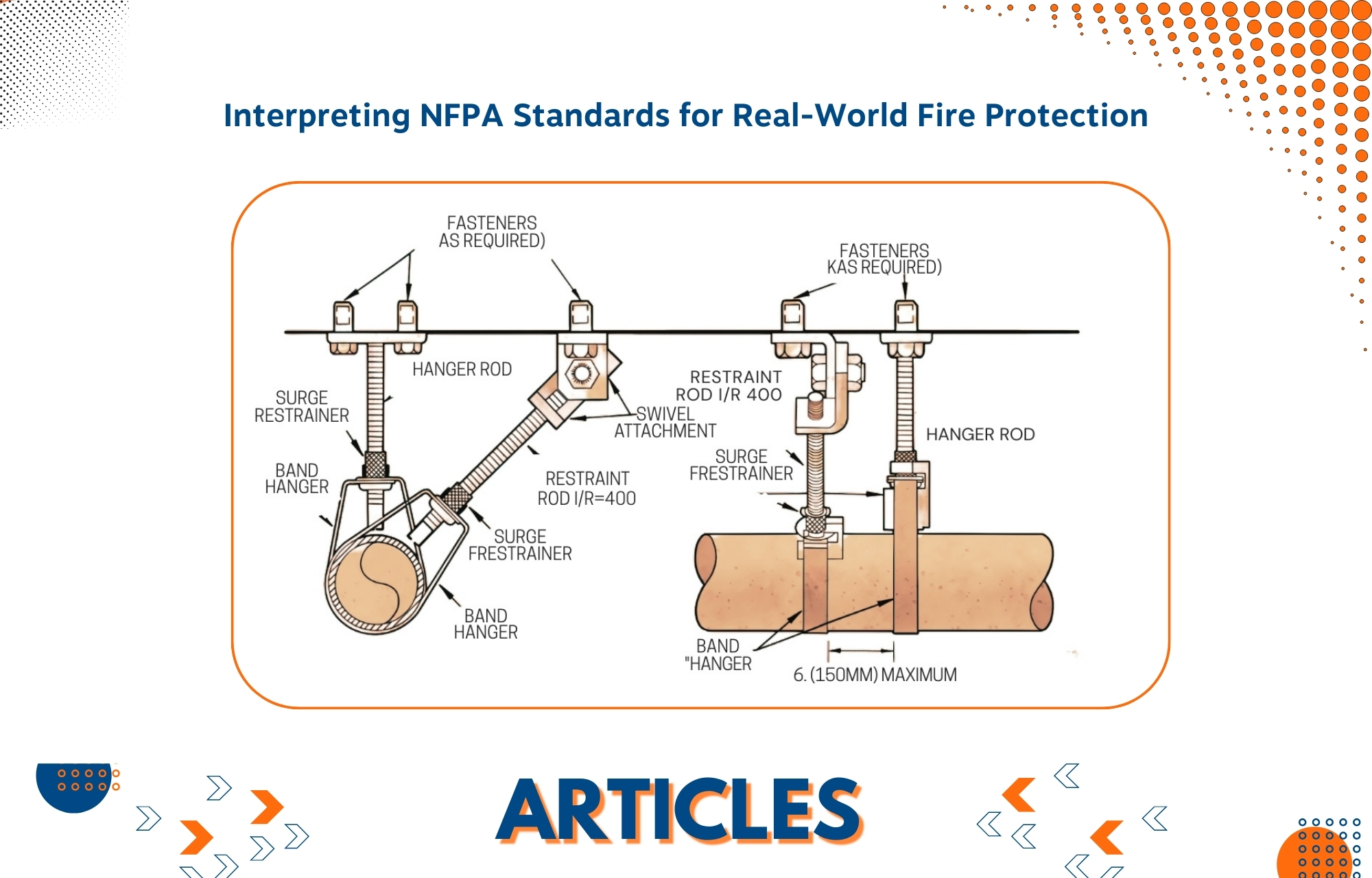

Question #6 – Branchline Restraint with Hangers and Thread Rod

According to Section 18.6.1(5) of the 2019 edition of NFPA 13, hangers set at an angle of at least 45 degrees from vertical and within 6 inches of a vertical hanger can be utilised as pipe restraints if the length-to-radius (l/r) ratio does not exceed 400.

Figures A.18.6.1(5)(a) and (b) show the limitation. According to A.18.6.1(5), installing hangers on both sides of a pipe does not limit the l/r ratio.

Question 6. Is it true that installing two restraints within 6 inches of a vertical hanger at 45 degrees and 135 degrees eliminates the l/r limitation?

Ans. Rods can be any length as long as they are installed in pairs on both sides of the branch line and at least 45 degrees from vertical. This is because one of the rods will be under tension. The l/r ratio determines the rod’s strength in compression rather than tension.

Question #7 – Flushing and Hydrostatic Test of a Backflow Preventer Upgrade

A backflow preventor assembly (BFP) is to be replaced, but no piping has changed.

Table 7.5.1 of NFPA 25 specifies that a hydrostatic test is required for pipe replacement rather than flushing. According to Section 6.10.2 of the 2022 version of NFPA 13, new pipe should undergo flush and hydrostatic testing.

Question 7. Is it necessary in this scenario to flush and perform hydrostatic testing?

Ans. No, hydrostatic testing or flushing is necessary. This would come under NFPA 25. NFPA 25 includes a table at the end of each chapter that summarises component replacement and action requirements. A table outlines required inspections and testing for system components during repair, replacement, or adjustment. Table 13.8.1 covers the replacement of a backflow preventor. The required inspections and tests are listed below:

(1) Check for leaks at system pressure as per Section 13.6.

(2) Conduct forward flow test as per 13.6.2.1

(3) Test supervisory device and alarm

(4) Conduct a main drain test (although a forward flow test is a better indicator of water supply and may be unnecessary).

Question #8 – Air Vent for Wet Systems

The system mostly uses CPVC piping, with a few feet of steel pipe at the floor control valve in the stair tower before switching to pure CPVC.

Question 8. Is an air vent necessary under the 2019 edition of NFPA 13?

Ans. Sections 16.7 and 8.1.5 of NFPA 13 2019 necessitate venting trapped air in wet pipe systems using metallic pipe. This standard aims to prevent corrosion by decreasing oxygen exposure in ferrous pipe systems.

In this instance, the system is CPVC. NFPA 13 defines a “system” as the pipe network that supplies water to sprinklers. CPVC is nonmetallic, which eliminates the need for venting due to corrosion. The presence of steel components at floor control valves does not make the system “steel.” These short metallic portions are only for fittings and valve connections, not system pipes.

Additionally, trapped air does not usually accumulate at floor control valves. To release it, simply operate the valve as per usual system operations. NFPA 13 does not require a separate air vent in a CPVC system with restricted steel pipe at valve assembly.

Question #9 – Distance Between Hose Valves-200 feet or 400 feet

This topic is about how to interpret NFPA 14 (2019), Section 7.3.2.2.1.1, which addresses the 200-foot travel distance regulation. It specifically asks whether the 200-foot distance extends from any place on a floor to the nearest hose valve, or if it reflects the maximum spacing between hose valves. The question is whether hose valves can be located 200 feet apart and provide up to 400 feet of total coverage.

Question 9. Is the 200-foot travel distance in NFPA 14, 2019 edition, Section 7.3.2.2.1.1 applicable per hose valve or the maximum separation allowed between hose valves?

Is the maximum travel distance between hose valves 200 or 400 feet?

Ans. Hose connections would typically be around 400 feet apart to cover the entire floor space.

NFPA 14, Standard for the Installation of Standpipe and Hose Systems, requires hose connections at each main landing or intermittent level as required by the Authority Having Jurisdiction (AHJ) for any interior or exterior exit stairs. NFPA 13 or 13R specifies a hose connection travel distance of 200 feet for fully sprinklered buildings and 130 feet for non-sprinklered buildings.

Hose connections must reach the whole floor space, measuring down the midline and 12 inches around corners.

In the 2024 edition of NFPA 14, sprinklered buildings may require an additional hose connection if the travel distance to the most remote area exceeds 200 feet, as determined by the AHJ. In previous editions, they were necessary for trip distances exceeding 200 ft.

Question #10 – Fire Pump Alarm and Signal Devices Remote from Controller

This issue asks whether it is permissible to display detailed pump indications (pump running, loss of phase, phase reversal, alternate source) as discrete zones on a fire alarm panel locally while simply sending a common fault signal to the remote monitoring station. The question is whether the NFPA requires each condition to be relayed individually for monitoring, or if a single consolidated signal is sufficient when the pump room is not constantly staffed.

Question 10. Is it acceptable to monitor pump running, loss of phase, phase reversal, and alternate source signals as separate zones on a fire alarm panel in the electrical room, with only a common trouble signal sent to the remote monitoring station if the pump room is not constantly staffed?

Ans. If the pump room is not constantly attended, it is acceptable to monitor pump running, loss of phase, phase reversal, and alternate source signals as separate zones on a fire alarm control panel in the electrical room. However, the signal from the control panel must be provided at a point of constant attendance.

NFPA 20, 2016 edition, Section 10.4.7.1 requires audible or visible signals powered by a source not exceeding 125 V to be provided in pump rooms without constant attendance. Section 10.4.7.2 requires fire pump alarms and signals to display information from 10.4.7.2.1-10.4.7.2.4.

If the fire pump room is not always staffed, the signals outlined in Sections 10.4.7.2.1-10.4.7.2.4 must be given at a location with consistent attendance.

The fire alarm control panel monitors and transmits fire pump signals to ensure constant attendance.

The standard aims to ensure that signals specified in Sections 10.4.7.2.1-10.4.7.2.4 are consistently received at a monitored location.

Question #11 – Clearance Around Control Valve

This topic asks if NFPA 13 requires a minimum clearance around sprinkler system control valves. The difficulty is guaranteeing adequate room for operation, inspection, testing, and maintenance. While NFPA 13 promotes accessibility, it does not specify a specific clearance dimension, leaving it up to good practice and AHJ interpretation.

Question 11. Is there a clearance minimum in NFPA 13 for control valves?

Ans. NFPA 13 does not specify a minimum clearance distance for a control valve. Consider practical installation and maintenance needs. When considering the size of a sprinkler riser closet, which often includes control valves, it’s important to understand that there is no standard dimension as each installation varies based on the equipment used.

According to the guidelines, workers should have at least a foot or two of space around equipment to install it and use tools. Smaller spaces may save space, but they can be more expensive and difficult to create and maintain over time. This is a practical guideline, not a rigorous code requirement.

Although there is no standard clearance requirement for control valves, industry best practices recommend at least a foot or two around the equipment for access and maintenance purposes. Ensure the installation allows for proper valve operation and servicing.

While NFPA 13 does not require a clearance, the 2024 International Building Code offers recommendations for fire pump and sprinkler riser chambers. According to Section [F] 902.1, rooms must be spacious enough to accommodate all installed equipment and provide enough working area around stationary equipment for inspection, servicing, and repair.

Replace without dismantling permanent structures or weakening fire-resistant assemblies. Additionally, doors and passageways must be large enough to remove.

The biggest piece of equipment.

NFPA 13 does not specify exact valve clearances, but building rules require rooms holding sprinkler system components to be safe and practical for long-term use.

Question #12 – Electric Cables on Sprinkler Pipe

A coordination problem has emerged on a hospital project in New Jersey. The cable tray in the corridor is located at the same level as the sprinkler branchlines. The general contractor has requested that the tray be broken to allow for straight sprinkler piping, with cables installed immediately on top of the pipe.

Question 12. Are there any rules in NFPA 13 or NFPA 25 that prevent wires from being put on top of sprinkler pipes?

Ans. Yes, NFPA 25 and NFPA 13 use comparable language. NFPA 13, Section 9.1.1.8.1 prohibits the use of sprinkler pipework or hangers to support non-system components.

According to NFPA 25, sprinkler piping cannot be subjected to external stresses from resting or hanging goods.

Closing Thoughts

These FAQs show how complicated and detailed NFPA standards may be. The codes are the main part of fire protection engineering, however many situations that come up in the field need careful interpretation. For example, NFPA 22 says that a water storage tank can be inside a protected building if the right fire exposure safety measures are in place. NFPA 25, on the other hand, says that freezers and coolers are not automatically considered hard environments unless there is evidence of corrosion or ice buildup. NFPA 13 also doesn’t require exact clearance around control valves, but it does stress that they should be easy to get to for operation and maintenance, allowing for site-specific conditions.

These examples show how important it is to not only know the code but also grasp what it means. Fire protection systems need to find a compromise between following the rules and being safe, practical, and reliable over time. Misunderstanding might cause extra costs, bad installs, or a drop in system performance. That’s why it’s important for professionals to stay up-to-date on the most recent NFPA editions, commentary, and advice from groups like the NFSA.

The main goal of NFPA standards is to make sure that fire protection systems work as they should when needed. Every part of the installation, from how the pipes are routed in crawlspaces to how far apart the hose valves are, affects how well the system works in a fire. This Technote gives professionals clear, useful information that helps them make smart choices by answering these real-world issues.

These kinds of concerns will keep coming up as the built world changes with new materials, technologies, and patterns. The best ways to make sure that fire safety systems stay up to date, strong, and useful are to stay informed, look up the requirements directly, and use expert resources. It is a useful guide for dealing with some of these problems and shows how important NFPA standards are for protecting lives and property.