Fire Water Pump Skid

It can be difficult to handle a weak water supply. If it is unable to deliver sufficient flow at the required suction pressure – which, in some regions, can’t be less than 20 psi. A pump on its own will not suffice, and you’ll need the recourse to suction tanks. The break tank, or variable speed pump might be the best solution if the flow is there but the static pressures remain an issue. The fire water pump must be able to handle the demand of the system, but not go over the system pressure regardless of the option that is picked.

Every Fire water pump installation is unique and the Rotaflow team members work to determine the most appropriate solution for each client’s requirements for Industrial fire pumps.

- Split Case Horizontal

- Split Case Vertical

- Vertical Turbine

- Packaged Skid Mounted

Rotaflow’s all pumps are ULC, UL and FM listed pumps.

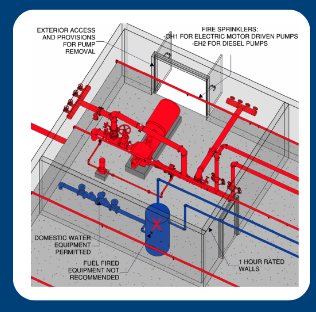

Rotaflow is using Navisworks software for the seamless design and replacement of our old fire water pump system.

Rotaflow is one-stop-shop for Fire protection and process safety solutions.

Let's build together. Bringing your ideas and innovations to life.

Contact Us

Please note that all forms and emails will be replied to within 24 hours. For immediate assistance, call 780-469-1220.

FAQ

Rated Fire Pump Capacity

A feature of pumps that is often misunderstood is that fire pumps don’t create flow. Instead they’re ineffective if the water supply is not able to provide the required flow. Fire pumps can only increase the water supply’s pressure. The total tension (differential pressure) at the rated flow and rated speed are shown on the nameplate of the manufacturer, as per NFPA 20. Every fire pump has the pressure of a particular flow. Similar to the flow specified the pressure that is specified is used as a reference. The flow of the fire pump and pressure are closely linked when the flow is increased the pressure drops and when the flow decreases, pressure increases.

Maximum Churn Pressure

Shutoff or churn often referred to as the pressure of the fire in the absence of flow, is restricted to not over 140% of the maximum for the pump’s pressure. The maximum pressure fire pumps are allowed to discharge, as an example at 182 psi, when there is no water flowing which is certified to discharge 130 psi at 500 grams per minute. Although the maximum pressure of each pump is 140 percent, however the limit for fire pumps that were centrifugal was previously 120 percent. Therefore, the majority of the centrifugal fire pumps that are available don’t exceed 120 percent of their rated pressure at the time of churn.

Minimum Fire Pump House Pressure

NFPA 20 specifies the lowest pressure that a fire pump is authorized to generate, as well as limit the churn’s pressure. Pumps must have at most 150 percent of the capacity of the rated capacity, or the minimum of 65 percent of the nominal head, in accordance with NFPA 20 Section 6.2.1. This means that the pressure has to be at or above 65 percent of the nominal tension at a 150 percent rate of rated flow. For instance, a fire pump that is rated at 130 psi at 500gpm has to be able to generate at minimum of 84.5 Psi at 775 grams per minute. In this article’s illustration, the pressure limits are illustrated.

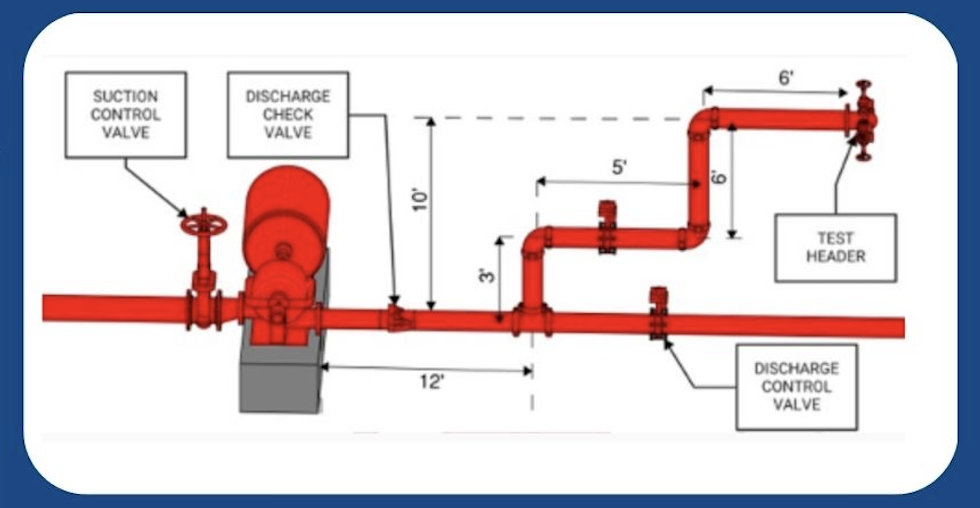

Fire Pump House Component Sizing

Its size has been the primary focus up to now however table 4.28 in NFPA 20 gives guidelines for parts. In accordance with the pump’s rating capacity, the chart shows the sizes that are required for the suction, discharge valves, relief valves, and testing headers. If the fire pump is functioning at the 150-percent mark of its nominal capacity, a speed that is 15 feet/second can be used in determining the amount of suction. The size of the supply lines used to connect the hose header is specified in the table however, if the supply line is more than fifteen feet long, it should be a pipe with a size larger than the diameter specified in the table. Alternatively, its length could be determined by hydraulic.

Threading the Needle

The initial part of the challenge is choosing a fire pump that will boost supply pressure to meet the requirements that the systems for fire prevention have. The maximum pressure the fire suppression system will stand up to will always be. While there are high-pressure connections, the standard highest pressure rating for the parts of the apparatus for fire prevention is 175psi. There are occasions when this pressure should be prevented. For example, ESFR sprinklers are only available with a 175 psi highest pressure. The churn pressure and static water pressure should be within the limits of maximum pressure ratings for the system’s components. The fire pump has to increase the pressure to a sufficient level to meet the demand.

It can be challenging based on the situation since some sources are not sufficient due to the steepness of the curve. This implies it is that static pressures are high, but that the pressure in residual is lower. There may be times when you are not capable of using a standard fire pump that is at a constant speed because of an extremely steep supply curve as well as excessive demands from the fire suppression. (Courtesy Jeff Dunkel)

It’s possible to use the variable speed fire pump when an automatic fire pump isn’t an alternative. With an adjustable speed fire pump pump’s speed could be altered to lower pressures for lower flows, resulting in an “flatter” curve, and use a bigger pump without worrying about high static pressures that are high. There are a few disadvantages of the variable rate fire pump the most significant of which is the size. The variable frequency drive (VFD) is a type of pump that can be quite large and must be integrated into the controller of electrical variable speed fire machines. Variable speed fire pumps have an inflated price as well as a bigger area. The dimensions and costs of diesel variable speed pumps aren’t affected as much. A pressure-limiting device (PLD) is employed by diesel pumps to alter the speed. While it can affect the costs, it does so in a less significant way than the variable frequency drive (VFD).