INTRODUCTION:

System types, a system demand pressure of more than 150 psi, and when an FDC solely offers maintenance for a portion of a building or a group of buildings are the three criteria for a fire department connection (FDC). Additionally, manual standpipes that are both “wet” and “dry” must be identified as such on the signs, and signage must also state the pressure required to satisfy system demand when it is greater than 150 psi. NFPA 13’s Section 9.2.1.2.2, which was added in the 2022 edition, states that a compartment that is only equipped with access panels and lacks doors is still considered to be a concealed area, even if a mechanical heating unit is present. Sprinkler location and position scenarios must follow NFPA 13R, according to Section 6.6.8. Concrete tee construction with members more than 7 to 12 feet apart is referred to be unobstructed construction. Cloud ceilings are constructed “in the same plane with horizontal openings,” and standpipes are not covered by IBC Section 1003.3.2.

The hose valve cannot protrude more than four inches beyond the minimum egress width or circulation channel. The minimum egress or stair width of 44 inches to bend around the landing is frequently accepted by code authorities. The arc or minimum stair width to the outer enclosure walls and corner is the outside clear width requirement of the stair and circulation path. The accessibility requirements of IBC Section 1003 and ICC A117.1 continue to apply to standpipes that are outside of this minimum clear width or arc. The hose connection may transgress 4 inches into the arc (circulation channel) as long as it is 27 inches or more above the floor.

Individual hose connections supplied by a riser that functions as a sprinkler and a standpipe, according to NFPA 13, are not horizontal standpipes but rather branch lines. A horizontal standpipe, according to portion 3.3.14.1, is a portion of the system’s piping that provides service to two or more hose connections on the same level. The standpipe pipe actually serves more than two hose outlets and must meet the pressure and flow requirements for hose connections on branch lines. Buildings with sprinklers throughout have a maximum flow rate of 1000 gpm, whereas all other structures have a maximum flow rate of 1250 gpm. The purpose of the five-year internal examination mandated by Section 14.2.1 is to find any materials that could prevent water from discharging from a sprinkler. Section 13.4.4.2.2.2 mandates the entire flow test in order to compare the system’s current performance to that of the first acceptance test. When the amount of time it takes for the water to flow steadily from the inspector’s test outlet increases by 50%, an obstruction inquiry is necessary. The major occupancy type’s danger categorization is not always applied to all parts of a school (or other occupancy types). A crucial component of fire sprinkler design is the classification of occupancy, which the competent design expert must take into account. In structures taller than 40 feet, interior storage of idle wood pallets is not explicitly protected by NFPA 13’s prescriptive standards. A maximum ceiling height of 30 feet is listed in Table 20.14.1.2(a), a maximum ceiling height of 40 feet is listed in Table 20.14.1.2(b), and a maximum ceiling height of 40 feet is listed in Table 20.14.1.2(c). This is because unused wood pallets can pose a serious fire risk. Residential sidewall sprinklers are required to have 4 inches of unobstructed space above the deflector without any impediments, according to Section 20.14 of NFPA 13 (2019). The minimum deflector distance is not respected in the scenario stated. Under a soffit, standard spray sprinklers are acceptable as long as the minimum and maximum distances are met.

Question #1 – FDC Labeling

A single building often includes several different types of standpipes (manual wet, automatic dry and automatic wet, combined, etc.) There are times when a single fire department connection serves multiple system types. In these cases, determining the proper signage can be confusing. Can the signage requirements of 2016 edition of NFPA 14 for the fire department connections be summarized?

Answer – According to the requirements, a fire department connection (FDC) must have three things. There are frequently local restrictions that must be taken into account.

- System kinds, such as whether the standpipe is manually operated and wet or dry .

- more than 150 psi for the system demand pressure

- When an FDC only provides maintenance for a piece of a building or a group of buildingsIt would be necessary to label a fire department connection that supplements or supplies both standpipe and automated fire sprinkler systems as a combined system. AUTOSPKR AND STANDPIPE” or “STANDPIPE AND AUTOSPKR” in 1-inch letters. (Sections 6.4.5.2.1 and 8.17.2.4.7 of NFPA 14) According to NFPA 14 Sections 8.17.2.4.7.2 and 8.17.2.4.7.3, signage must additionally indicate the pressure needed to meet system demand when it is more than 150 psi. Additionally, manual standpipes that are both “wet” and “dry” must be designated as such on the signs. (2016) NFPA 14 Section 6.4.5.2 With a minimum of 2 – 2 12 inlets and a maximum of 5 – 2 12 inlets for a building that is fully sprinklered through in accordance with NFPA 13R, combined FDC must be sized to the system demand of the sprinkler or standpipe system, whichever is greater (Section 7.10.1.1.5).

Question #2 – Air Vent Sign

Would a sign, similar to an auxiliary drain sign, need to be provided with an air vent. Based on the summary found in A.16.17 and the air vent section it does not appear as if one is required. Is it a requirement to provide an identification sign for an air vent?

Answer –

NFPA 13 (2019 edition), Section 16.9.12.1, mandates that “All control, drain, venting, and test connection valves shall be provided with permanently marked weatherproof metal or rigid plastic identification signs.”

From a practical standpoint, it is crucial to have indications available so that they may be properly identified in the future.

Question #3 – Closet vs Concealed Space – NFPA 13R

An apartment building is to be equipped with a sprinkler system in accordance with the 2019 edition of NFPA 13R. There is a mechanical heating unit (electric) in a corner of the room with walls on all four sides. There are no doors into this space but there is an access panel/louver for maintenance purposes.

There is confusion as to if this space would be considered a “closet” or a “concealed space”. If this is considered a closet, then section 6.6.4 of the 2019 edition may apply which requires sprinklers in closets with heating or air conditioning equipment. However, if this space is considered a concealed space, then sprinklers are not required in accordance with section 6.6.6.

Is this space considered a closet or a concealed space?

The answer is that rather than a closet, the stated location would be classified as a concealed space. This is reinforced by wording in the NFPA 13 2022 edition.

In the 2022 version of NFPA 13, Section 9.2.1.2.2 was introduced, which stipulates that areas “shall be considered a concealed space even with non-fuel-fired equipment and access panels.”

The purpose of adding this idea to NFPA 13 was to make clear the precise circumstance that has been stated. This clause indicates that a compartment without doors and simply outfitted with access panels is regarded as a concealed area regardless of the existence of the mechanical heating unit.

Section 6.6.8 expressly stipulates that sprinkler location and position scenarios “that are not directly discussed by NFPA 13R shall be in accordance with NFPA 13” even though this phrase is not included in NFPA 13R.

Since this area would be regarded as a concealed space, NFPA 13R’s section 6.6.6 would be applicable, which clearly specifies that sprinklers are not necessary in concealed spaces.

Question #4 – Obstructed Construction

NFPA 13, 2019 edition, Section 3.3.41.1 defines obstructed construction and the annex (A.3.3.41.1(2)) provides the example of concrete tee construction as obstructed construction, but no dimensional limitations are provided in the example. All other examples of obstructed construction in NFPA 13 Annex are described with dimensional limitations, such as panel construction. The lack of dimensional limitations for the concrete tee examples makes these examples unclear.

Is concrete tee construction with members approximately 8 feet on center creating an area between beams exceeding 300 square feet obstructed construction?

Answer- No, unobstructed construction is defined as concrete tee construction with members more than 7 12 feet apart. Concrete tees or other structural parts that are more than 7 12 feet apart are considered to be unobstructed construction under Section 3.3.41.2. There would be a smooth, level ceiling in the space between the beams or tees, and this would be regarded as unimpeded construction.

Question #5 - Are Pipe Schedule Systems limited to Ordinary and Light Hazard Occupancies?

There is a building with an existing Ordinary Hazard pipe schedule system. The owner is planning to add rack storage of Class II commodities stored no higher than 12 ft. It is being discussed if the pipe schedule system can be modified for this use. Three questions were asked:

- Where in the 2022 edition of NFPA 13 does it state that pipe schedule systems are only allowed in Light and Ordinary Hazard systems?

- When was the Extra Hazard schedule discontinued?

- Can pipe schedule systems be used to protect rack storage typically limited to 12ft (low pile) storage as OH system?

There were three queries.

Q.1 Can you perhaps tell out in the standard which sections exclusively refer to OH2 systems for pipe scheduled systems?

A1: Modifications to existing additional hazard occupancies as well as new and existing light hazard and ordinary hazard occupancies are permissible when using the pipe scheduling system approach. In brand-new extra-hazardous occupancies, it is unacceptable. This criterion may be found in Sections 19.2.2.3 and 28.5.1.2 of the NFPA 13 version for 2022.

- improvements and alterations to current pipe scheduling systems

- adjustments and additions to the extra-hazard pipe scheduling systems currently in place

- less than 5,000 square feet in new systems

- New systems of limitless size that satisfy the flows shown in Table 19.2.2.1 (at a maximum elevation of 50 psi residual pressure)

Section 28.5.1.2 specifies that the following must be hydraulically determined in order to further restrict the usage of the pipe scheduling method:

- sprinkler systems that are not 5.6K

- Other pipe systems beyond those listed in Table 7.3.1.1

- Systems with additional hazards (groups 1 and 2)

- exposure mechanisms

Furthermore, extra danger occupancies must be hydraulically estimated, according to Section 28.5.4.

The body of the standard does not provide any pipe schedule tables other than for light and ordinary hazard, hence new pipe schedule systems are also restricted to light and ordinary hazard occupancy.

Q.2 What year did the additional danger schedule end?

A2: In the 1991 version of NFPA 13, the additional hazard pipe schedule systems tables (for new systems) were eliminated. The annexe section A.28.5.4 does provide a table for additional hazard pipe schedule systems since the pipe schedule system can still be used to alter current extra hazard pipe schedule systems.

Q.3. Can pipe schedule systems be employed as an OH system to safeguard rack storage, which is normally just 12 feet (low pile) storage?

A3: While NFPA 13 does not specifically address the use of pipe schedules with storage (low-piled or high-piled), the argument can be made that the pipe schedule system would be appropriate for the ceiling system in this situation as long as K-5.6 sprinklers are used because low-piled storage is frequently protected as an ordinary hazard. In-rack sprinklers must be placed in compliance with section 25.2.2 (see section 4.3.1.7.2.2) if they are to be used. According to chapter 25, it is not appropriate to size the in-rack sprinklers based on pipe schedules.

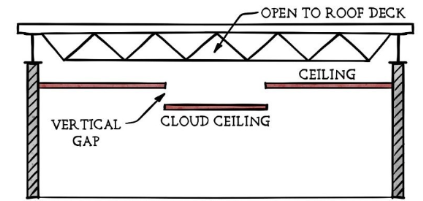

Question #6 – Vertical Cloud Ceiling Gap to Existing Upper Ceiling

There is an unconventional cloud ceiling with a vertical gap between the cloud ceiling and the upper ceiling above.

can the “cloud ceiling” provisions of the 2016 edition of NEPA 13 be used to omit sprinklers above the clouds?

Answer- No, the provision on cloud ceilings (and the study upon which it was founded) solely covers cloud ceilings at a single horizontal plan with horizontal apertures. The prescriptive requirements of the standard do not permit vertical apertures in a cloud ceiling in the manner indicated.

The definition of cloud ceiling in Section 3.3.5.1 elaborates on this idea. A cloud ceiling is built “in the same plane with horizontal openings,” according to this definition. According to this definition, the stated configuration is ineligible to make use of the clauses in Section 8.15.24 that permit sprinklers to be excluded above this ceiling construction.

Question #7 –Building Code Provisions for Protruding Objects in Stairwells and Standpipes

Are hose valves attached directly to vertical standpipe in stairways, which are outside of the egress path subject to the post mounted object rules in Section 1003.3.2 of the 2018 edition of the International Building Code (IBC)?

Because it is neither a post or pylon, the standpipe is not covered by IBC Section 1003.3.2, although the same guidelines in the following Section 1003.3.3 do apply to standpipes. In other words, the hose valve cannot extend more into the circulation path/minimum egress width than four inches.

Code authorities frequently accept the minimum egress or stair width of 44 inches to curve around the landing. The outside clear width requirement of the stair and circulation route is the arc or minimum stair width to the exterior enclosure walls and corner. The IBC Commentary’s Figure 1007.3.1, which depicts the “arc” of the minimum required width as necessary, supports this. It is not the intent of this section to require that a stairway landing be shaped as a square or rectangle, as long as the landing provides an area described by an arc with a radius equal to the actual stairway width, according to another illustration from the same commentary (1009.5) on landing width. The same arc in the stair enclosure is also specified in NFPA 101, Life Safety Code Handbook, Section 7.2.

IBC Section 1003 and ICC A117.1’s accessibility rules still apply to standpipes that are outside of this minimum clear width or arc. All individuals passing through the building, whether physically able-bodied and impaired, are addressed by this section (1003) and the A117.1 code. Consider a blind person coming down the stairs. What may be in their way that they can’t see or feel, or what would jut out and hurt them? Because the standpipe is continuous from floor to ceiling, it must still adhere to IBC/ANSI standards even when it is outside the minimum egress width arc. As long as the hose connection is 27 inches or more from the floor surface, it can encroach 4 inches into the arc (circulation channel). Up to 80 inches, the same 4-inch rule (1003.3) applies.

Question #8 – Horizontal Standpipes

Section 7.10.1.2.2 in the 2013 edition of NFPA 14 is for a horizontal standpipe that serves three or more hose connections on any floor. A system includes several hose connections dropping from the sprinkler system at their own independent location.

Do systems that supply two hose connections need to meet the requirements of this section? If not, does that mean these setups have no flow/pressure requirement?

Individual hose connections fed by a riser that serves as both a sprinkler and a standpipe are not considered horizontal standpipes; instead, they are branch lines. Branch lines are described as not more than one hose connection on a piping system connecting to a standpipe system in the 2013 edition of NFPA 14, Standard for the Installations of Standpipes and Hose Systems (Section 3.3.2).

According to Section 3.3.14.1, a horizontal standpipe is a section of the system’s piping that serves two or more hose connections on a single level. The criteria of Section 7.10.1.1.2 must be fulfilled when a horizontal standpipe delivers three or more hose connections, adding an extra 250 gpm to the computation for a total of 750 gpm.

The pressure (Section 7.8) and flow (Section 7.10) specifications for hose connections on branch lines must be met. They are there for convenience, but they really create extra standpipes that must be taken into account when performing hydraulic calculations.

According to Section 7.10.1.1.6, when a lateral pipe serves a single hose connection, the system’s flow must be calculated as though the hose connection is being supplied by a separate standpipe.

The standpipe pipe actually serves more than two hose outlets, according to the annexe note for Section A.7.10.1.1.6, which suggests that the hydraulic calculations be taken in accordance with Figure A.7.10.1.1.6 and an additional 250 gpm calculation is taken from the most remote standpipe. The standpipe pipe actually services more than two hose outlets.

According to NFPA 13, the maximum flow rate for buildings with sprinklers throughout is 1000 gpm, whereas for all other structures it is 1250 gpm.

Question #9 – 3-year and 5-year tests in NFPA 25

The NFPA 25 (2011) mandated five-year internal assessment was recently completed on a building, however it was noted that the required 3-year flow test of the dry pipe system was not performed.

Does the five-year internal assessment satisfy the requirements for the three-year flow test of the dry system?

Answer- No, the three-year full flow test of a dry pipe system criteria are not met by five-year internal evaluations.

The purpose of the five-year internal examination mandated by Section 14.2.1 is to find any materials that could prevent water from discharging from a sprinkler. Section 13.4.4.2.2.2 mandates the entire flow test in order to compare the system’s current performance to that of the first acceptance test. According to Section 14.4.3.1 (14) of the code, Section 14.3.2 requires an obstruction inquiry whenever there is a 50% increase in the amount of time it takes for water to flow steadily from the inspector’s test outlet.

An obstruction inquiry is needed if triggers are found in line with Section 14.3.1; it is not frequency-based.

Question #10 – Occupancy Classification for Accessory Rooms

A sprinkler system is being designed for a school and it was noted that the small room rule which is limited to light hazard occupancies is being applied to areas such as mechanical rooms.

Can accessory spaces of a school be lumped into the light hazard classification, or is further investigation of the contents of the room justified? Does the 2013 edition of NFPA 13 have a section similar to the Section 311.1.1 in International Building Code?

Answer- No, each room in a school (or other form of occupancy) is not automatically given the same level of danger as the main type of occupancy; instead, extra research is required to determine the combustibility, volume, and rate of heat release of each room’s contents.

According to The 2013 Automatic Sprinkler Handbook, a typical classroom is meant to be characterised by the categorization of light danger for educational purposes as mentioned in the general examples given in Annex Section A.5.1. There may be other locations of the school that require a higher occupancy danger classification, such as janitor closets or storage/mechanical/electrical/chemistry prep rooms. Once more, this assessment is made by taking into account the related contents’ volume, height in storage, combustibility, and rate of heat release.

According to the NFSA’s general statement on this subject, which is listed below, classification of occupancy is a crucial component of the fire sprinkler design:

Except in cases where an NFPA committee has expressly addressed the topic, questions about danger or commodity categorization are challenging. This is particularly true given that categorization is seen as the most crucial component of fire prevention system design and a duty of the responsible design expert in many jurisdictions. The need for a responsible design expert is mandated by several states in part to guarantee that the project’s site-specific characteristics be acknowledged and appropriately addressed, which cannot be done in a generic way.

The IBC section 311.1.1 for occupancy classification, which typically specifies that the storage spaces that are connected with a given occupancy are categorised as part of that occupancy, is comparable to the statement in NFPA 13 for hazard classification.

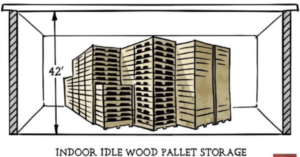

Question #11 – Idle Wood Pallets stored Indoors

A warehouse with a ceiling height of 43 ft. will include rack storage of idle wood pallets within the building. The highest maximum ceiling/roof height indicated in the 2019 edition of NFPA 13 in Table 20.14.1.2(c) is 40 ft.

Is indoor storage of idle wood pallets allowed in buildings with a maximum roof height above 40 ft?

Answer- NO, according to the standards of Section 20.14, Protection of Idle Pallets, in the 2019 edition of NFPA 13, there are no mandatory requirements to safeguard interior storage of idle wood pallets in structures taller than 40 feet.

- Table 20.14.1.2(a) specifies a 30 foot ceiling height for CMDA sprinklers.

- Table 20.14.1.2(b) specifies a 40-foot ceiling height for CMSA sprinklers.

- Table 20.14.1.2(c) specifies a 40-foot ceiling height for ESFR sprinklers.

This restriction is due, in part, to the serious fire risk that unused wood pallets might provide. Stacks of empty pallets are one of the biggest obstacles sprinklers must overcome, as stated in the annexe in A.20.14. Pallet undersides provide a dry region where a fire might start and spread to other pallets. Until the fire breaks through the top of the stack, this process will continue. Ceiling sprinklers might not be able to put out this high-risk fire at this stage. The provisions of Section 20.14 are utilised to lessen these difficulties because of the dangerous fire conditions that might result from idle pallet storage. A protective standard not included in this section would fall beyond the purview of NFPA 13.

Question #12 – Sidewall sprinkler with duct two inches above.

A residential sidewall sprinkler (listed to be installed 6 in. to 12 in. below the ceiling) is installed 12-inches below the ceiling. A 10 in. deep duct is being installed directly above the sidewall sprinkler. The distance from the deflector to the duct is to be 2 inches.

Can a duct be installed 2 inches above the residential sidewall sprinkler as long as the maximum distance below the ceiling is maintained?

Answer- The description suggests that the response is “no.” For extended coverage sidewalls and residential sidewall sprinklers, there must be 4 inches of unobstructed space above the deflector without any impediments.

The sprinkler deflector must be 4 inches away from the ceiling under Section 6.4.6.2.1 of the 2019 version of 13R. Only 2 inches must separate the deflector from the duct above in the specified layout, which is against the rules.In this instance, the issue is the minimum necessary distance rather than the maximum distance between the deflector and the ceiling.

It should be noted that NFPA 13 (2019), for normal spray sidewall sprinklers beneath soffits, expressly mentions a similar idea. Standard spray sprinklers may be installed beneath a soffit as long as “both the minimum distance from the sprinkler deflector to the bottom of the soffit and the maximum distance from the sprinkler deflector to the high ceiling is maintained,” according to Section 10.3.5.1.3.3 and its annexe figure. Once more, the minimum deflector distance is not upheld in the scenario stated.

Courtesy: This edition of TechNotes was written by Jeffery Hugo, Vice President of Codes, Standards, and Public Fire Protection for the National Fire Sprinkler Association.