The following are a dozen of questions answered keeping in mind various Codes, Standards related fire sprinkler system.

Question #1 – In-Rack Sprinklers – Quick Response or Standard Response

A project includes solid racks that require in-rack sprinklers with an ESFR system at the ceiling installed in accordance with the 2016 edition of NFPA 13.

Are the in-rack sprinklers required to be quick response or are standard response sprinklers acceptable?

Unless a special design criterion is being employed that authorises the use of standard response in-rack sprinklers, in-rack sprinklers with an ESFR ceiling design must be rapid response.

The general specifications are included in Section 8.3.3, Thermal Sensitivity, of NFPA 13, 2016 edition. Where quick-response sprinklers are placed, section 8.3.3.2 says that, unless otherwise authorised in 8.3.3.3, 8.3.3.4, or 8.3.3.5, all sprinklers inside a compartment must be quick-response. In-rack sprinklers, however, are exempt from the rules of 8.3.3.2, according to Section 8.3.3.4.

The criteria for in-rack sprinklers, including the heat sensitivity, are given together with the chosen design strategy in the storage chapters (Chapter 12–21). The categorization of the commodity, the method of storage, and the kind of protection (CMDA, CMSA, or ESFR) chosen would all affect this choice.

For instance, Section 17.2.3.4.2 mandates that the in-rack sprinklers be K-8.0 or K-11.2 quick-response, ordinary-temperature sprinklers if the project involves rack storage of plastic commodities up to and including 25 ft in height with ESFR ceiling protection. The comments in the guidebook on this part continues by saying that the only circumstance in which in rack sprinklers must be rapid response is when the ceiling sprinklers are ESFR. The in-rack sprinklers should have a similar sensitivity as the ESFR sprinklers at the ceiling in order to start controlling the fire before the ESFR sprinklers farther away from the fire activate.

When solid shelves are utilised in projects that involve rack storage for plastic goods exceeding 25 feet in height with ESFR ceiling protection, Section 17.3.3.1.1.1 mandates that in-rack sprinklers be placed on every level below the tallest solid shelf. According to Section 17.3.3.4, one level of K-8.0 or K-11.2 quick-response, ordinary-temperature in-rack sprinklers must be installed where specified by Table 17.3.3.1. These sprinklers must be put at the tier level that is closest to, but does not exceed, one-half of the maximum storage height.

The similar requirement for in-rack sprinklers to be rapid response is found in Sections 16.2.3.6 and 16.3.3 for rack storage of Class I through Class IV commodities where ESFR sprinklers are being employed at the ceiling.

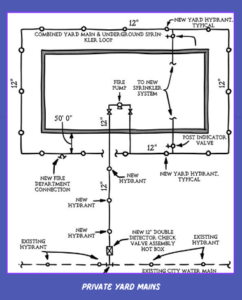

Question #2 – Private yard mains

A project consists of a large building that is to be equipped with an ESFR fire sprinkler system. There is a 12-inch underground service from the city water main which will feed a fire pump within the building. The fire pump, in turn, will feed a 12-inch underground loop. This yard loop will feed both the sprinkler lead-ins and private fire hydrants. See Figure below.

Is this arrangement acceptable?

It is correct that NFPA 24, Standard for the installation of Private Fire Service Mains and Their Appurtenances, would apply to this private fire main. The underground loop may be supplied by a fire pump, according to NFPA 24. This is made obvious in Section 5.6 of the NFPA 24 2022 edition, which specifies that fire pump units erected in compliance with NFPA 20 should be regarded an appropriate water supply (same language in prior versions). It is made clear in the annexe to this Section (A.5.6) that the specified arrangement is permissible. According to the annexe to this part, a fire pump and suction supply “makes an acceptable supply” if it has sufficient capacity, dependability, and is situated appropriately.

The pipe on the fire pump’s discharge side needs to be rated for the pressures it will be subjected to.

Sectional valves as described in Section 6.6 must also be provided. According to this rule, sectional valves must be provided such that there are no more than six fire protection connections between sectional valves. This criterion, as mentioned in annexe Section A.6.6.1, is intended to reduce the number of connections that would be harmed as a result of a pipe break or during system repairs. The term “fire protection connections” is also used in this annexe remark to refer to “sprinkler system lead-ins, hydrants, or other fire protection connections.”

It should be noted that this criterion is only applicable to looping systems under the new version of this section (6.6.1) that was published in 2022. It was not made clear in earlier editions that this criterion only applied to looping systems. However, the need for sectional valves for this project would be true regardless of whatever edition is being enforced.

Question #3 – Paint Booth with exterior exhaust

Sprinklers are being installed in a paint spray booth in accordance with the 2013 edition of NFPA 13. The exhaust duct from the booth runs up the exterior of the building.

Is it required to provide protection for the exterior portion of the exhaust duct?

The exhaust duct must include sprinkler protection, and this protection must extend to the duct’s outside parts.

Spray areas must be secured by an authorised automated fire protection system, according to Section 9.1 of the 2011 version of NFPA 33 (which is cited by the 2013 edition of NFPA 13). The spray area is defined in this section as “any associated exhaust plenums and exhaust ductwork.”

According to NFPA 33’s Section 3.3.2.3, a spray area consists of the following:

1.areas directly affected by spray application

2. Inside of the paint booth

3.the exhaust plenum’s interior

4.within the exhaust duct

5.the air recirculation filter’s inside

6.unit for the recovery or concentration of solvents

The remainder of this definition highlights regions that are not included in the spray area and so do not need to be protected. These territories consist of:

1.devices that provide fresh air

2.Plenums and ducts for air supply

3.ducting for the delivery of recirculated air that are below secondary filters.

4.solvent concentrator units’ exhaust ducts.

According to this definition, the exhaust duct is included in the spray region, necessitating sprinkler protection. Exhaust ducts that are located on a building’s outside are not specifically mentioned in NFPA 33.

Sprinklers guarding ducts or stacks “shall be spaced no more than 12 ft apart,” according to Section 9.4.6 of the 2011 version of NFPA 33.

The sprinkler distance between vertical and horizontal ducts was the same in the 2011 version; however, this part was updated in the 2016 edition. The 2016 edition’s Section 9.4.6(1) states that “one sprinkler shall be located at the top of each vertical riser and at the midpoint of each riser.” If the rise is larger than 7.3 m (24 ft), additional heads must be placed at intervals of 7.3 m (24 ft). According to Section 9.4.6 (2), sprinklers in the horizontal part of ducts must be placed 12 feet apart, starting no farther than 6 feet from the duct entry.

Question #4 – Cloud ceilings and hydraulic calculations

A project includes cloud ceilings; however, sprinklers are required to be installed both above and below the ceiling clouds as the clouds do not meet the requirements to omit sprinklers above in accordance with 8.15.24.1 of the 2016 edition of NFPA 13.

When determining the hydraulically remote area, is the calculation required to include the sprinklers above and below the clouds?

No, the sprinklers in the ceiling clouds are only there because the sprinklers above are blocked by the clouds. The ceiling sprinkler calculations may expressly eliminate the sprinklers beneath impediments per Section 23.4.4.7.3.1. The widespread consensus is that the sprinklers above are intended to tackle the issue below. Because they are just that much closer to the fire if the sprinklers below the clouds activate, they will aid in preventing an equal number of sprinklers above the ceiling from activating.

It should be noted that, according to this idea, the sprinklers for higher ceilings must be constructed to account for the distance from the floor to the higher ceiling. Therefore, the decrease must be based on the height of the higher ceiling sprinklers, not the cloud ceiling sprinklers, if rapid response sprinklers are used to lower the design area.

Question #5 Minimum size for a combined standpipe

It appears that Section 7.6.3 of the 2013 edition of NFPA 14 requires that combined sprinkle/standpipe risers be at least 6 in. in size.

Is there an exception to use 4 in. if the standpipe calcs work hydraulically?

If sprinklers are installed throughout the structure, the standpipe pipe size can be 4 inches if the hydraulic calculations support the design. When a building is hydraulically engineered in accordance with Section 7.8.1 and is protected throughout by an NFPA 13 or 13R system, Section 7.6.3 permits the installation of a minimum 4-inch standpipe pipe.

As stated in Section 7.6.1, the minimum standpipe pipe size is 4 inches, and Section 7.6.2 specifies that all standpipes that are a component of a combined system in partly sprinklered buildings must have a minimum 6 inch pipe.

In order to better address this in the 2016 edition, the technical committee added “where only a portion of the building has sprinkler protection” to Section 7.6.2 and clarified the exception in Section 7.6.2.1, allowing the 4 in. pipe for systems hydraulically designed in accordance with Section 7.8.1. This public remark was justified on the grounds that it clarifies when a riser must be 6 inches tall as well as the link between Sections 7.6.2 and 7.6.3.

The technical committee continues to clarify this matter in the 2019 edition of the standard by once more making sub-section 7.6.2.1 a stand-alone requirement in Section 7.6.3. The committee said that “AHJs still don’t believe that a standpipe can be 4 in. when the building is sprinklered throughout,” which was used to justify the adjustment. Even though the building is sprinklered all around, the AHJs are not permitting the standpipe to be 4 in. since this comes under 7.6.2.1. The committee voted unanimously to support this amendment.

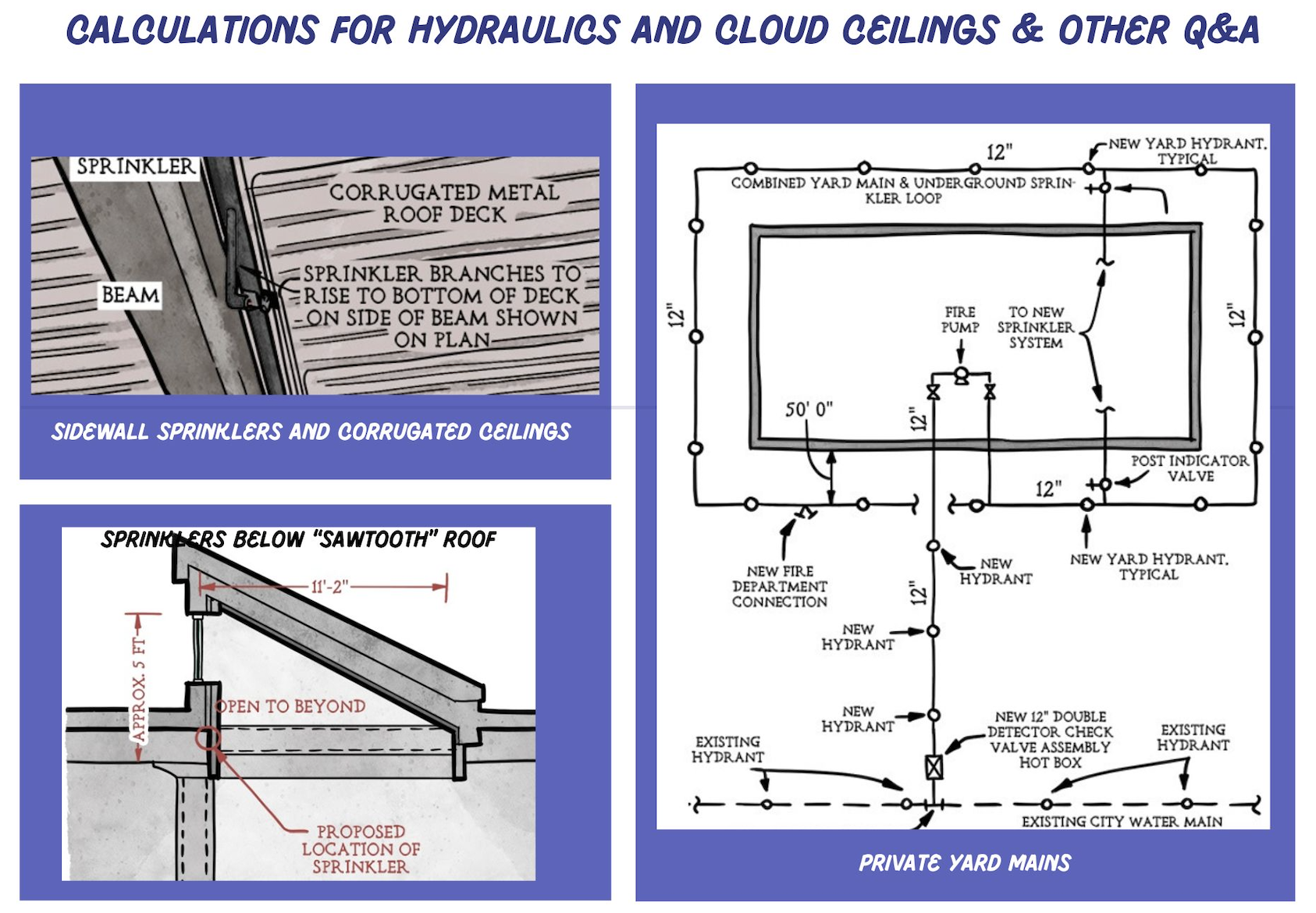

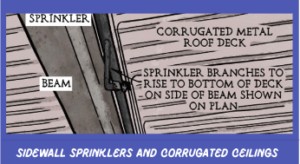

Question #6 – Sidewall sprinklers and corrugated ceilings

For aesthetic reasons, the architect is wanting to install rows of horizontal sidewall sprinklers parallel and tight to the structural beams in the new shop. The ceiling between the structural beams consists of 3 in. corrugated metal. The referenced edition of NFPA 13 is the 2016 edition.

Is the ceiling considered to be smooth flat as per the listing of the sidewall sprinkler?

Yes, it would be deemed smooth and flat to say the ceiling between the beams. The smooth ceiling classification as stated in Section 3.3.5.5, which indicates that a smooth ceiling is “free from significant irregularities, lumps, or indentations,” is unaffected by the 3 in. corrugations. According to the distinction indicated in Section 8.5.4.1.2 on the measuring of deflector to ceiling distances, corrugations up to and including 3 inches in depth shall be regarded as smooth.

The 2022 version of NFPA 13 provides more support for this. A smooth ceiling is one that is “free from significant irregularities, lumps, or indentations greater than 4 in. in depth,” as stated in section 3.3.28.4 of the current edition of the standard. Furthermore, section 10.3.2.1 now specifies that “corrugated metal decks with channel depths up to 3 in. shall be considered as smooth ceilings.”

Question #7 – In-rack sprinkler calculations

In a warehouse project, protected in accordance with the 2013 edition of NFPA 13, there are in-rack sprinklers in a portion of the building. The most hydraulically remote area for the ceiling sprinkler does not coincide with the area with in-rack sprinklers. Section 23.8.2 states that the water demand for in-rack sprinklers must be added to the ceiling demand at the point of connection.

Is it required to provide calculations for the overhead systems most remote area without in-rack demand added (no racks below), as well as additional calculations with overhead design area adjusted to be above the most hydraulically demanding in-rack sprinklers?

Yes. Only the ceiling sprinkler demand in the same area as the in-rack sprinklers has to be added to and balanced with the in-rack sprinkler demand. Since in-rack sprinklers are not present in the hydraulically most demanding location (the distant area in this example), the in-rack demand does not need to be added to and balanced with the ceiling demand.

But the space with the in-rack sprinklers would need to be subject to an extra calculation. The most demanding area of the ceiling sprinkler above the in-rack sprinklers would be added to and balanced with the in-rack demand below in this computation. The commentary to Section 23.8.2 of the Automatic Sprinkler System Handbook (2013) provides a description of this idea.

Question #8 – Ceiling Pockets along a wall

There is a project that includes a ceiling pocket along a wall with a lower ceiling on one side only. This pocket meets the criteria of Section 8.6.7.2 in the 2016 edition of NFPA 13 to allow the omission of sprinklers from within the pocket.

Does this section to allow sprinklers to be omitted from pockets along a wall where sprinklers are only spaced on one side?

Yes. Six requirements are listed in Section 8.6.7.2, and if all six are met, sprinklers inside the ceiling pocket are prohibited. Sprinklers are not required in ceiling pockets that are adjacent to a wall so long as a lower sprinkler protects the area below the unprotected pocket.

Question #9 – Sprinklers under obstructions

Section 8.5.5.3.1.1 in the 2016 edition of NFPA 13 allows sprinklers below obstructions to be located up to 3 in. from the outside edge of the obstruction.

Does this section apply to all sprinkler types (Standard Spray, CMSA and ESFR)?

Yes, all sprinkler types are covered under Section 8.5.5.3.1.1. This is made apparent by Section 8.5.1.3, which specifies that, unless Sections 8.6 through Section 8.12 have more stringent restrictions, Sections 8.5.2 through Section 8.5.7 applies to all types of sprinklers.

Additionally, Section 8.5.5.3.3 specifies spray, CMSA, ESFR, and residential sprinklers as being equivalent to those installed at the ceiling, with the exception of Section 8.5.5.3.3.1, which allows the use of spray sprinklers under overhead doors.

Question #10 – Sprinklers below obstructions in sound stages

A project includes sound stages which in accordance with Section 22.19.2.2 in the 2016 edition of NFPA 13 is being designed as extra hazard group 2. It is our interpretation, that this higher design density is to avoid sprinkler heads below temporary sets/ceilings that occurs within a studio sound stage. It has been stated that this same section can be used to avoid installing sprinklers below permanent obstructions like ductwork and catwalk over 4 ft wide.

If a soundstage is designed to an Extra Hazard Group 2 per Section 22.19.2.2, can sprinklers be omitted from below permanent obstructions like ductwork and catwalk over 4 ft wide?

No, according to Section 22.19.2.2, if the sprinkler system for a building satisfies the design standards for Extra Hazard, Group 2, NFPA 13 provisions banning impediments to sprinkler discharge are not applicable. Although it is impracticable to safeguard all blockages for each change in set, this alternate design criterion is offered to take into consideration the building of props and settings that vary often. Only impediments that fit those requirements should be subject to this section. According to Chapter 8, the structure’s and permanent equipment’s fixed impediments must be safeguarded.

The NFPA 140: Standard on Motion Picture and Television Production Studio Soundstages, Approved Production Facilities, and Production Locations, 2013 version, is where this criterion was taken from. It is advised that all of the protection criteria in NFPA 140 be examined, especially Section A.4.11.1.3.1, which gives a thorough justification for the existence of the alternative design criteria.

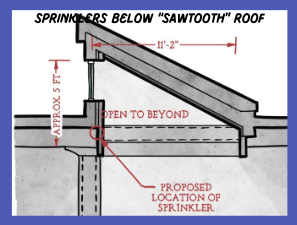

Question #11 – Sprinklers below “sawtooth” roof

A project includes an area 32 ft x 11 ft with a sawtooth pattern raised ceiling, sort of like a skylight. This ceiling jumps up approximately 5 ft on one side to allow vertical windows and then the ceiling slopes back down to the original 9 ft high ceiling which surrounds this area.

Since this area is over 32 sq ft, it cannot be treated like an unprotected skylight. And since it is over 36 inches tall on one side, it cannot be treated as an unprotected ceiling pocket.

In this scenario, would it be acceptable to have sidewall sprinklers approximately 4 ft-6 in down from the peak, spraying horizontally straight across this ceiling?

No, there is no prescribed procedure in NFPA 13 that would allow a sidewall sprinkler to be placed with a deflector distance of 4 ft 6 in below the highpoint of the ceiling. Sidewall sprinklers must be installed with the deflector no higher than 6 inches from the ceiling (may be up to 18 inches when specified for such purpose), as stated in section 8.7.4.1.1.

The deflector must also be positioned parallel to the ceiling per section 8.7.4.2.1. In addition, according to Section 8.7.4.2.2, sidewall sprinklers for sloping ceilings (like the one just described) must be placed at the “highpoint of the slope and positioned to discharge downward along the slope.”

You are right that the situation stated would not allow the deletion of the skylight (8.5.7) since the space exceeds 32 square feet, or the ceiling pocket (8.5.7) because the depth of this “pocket” exceeds 36 inches.

It seems that the possibilities in this circumstance are just as follows:

1.Sprinkler(s) should be installed in this “pocket” while sticking to the recommended deflector distances. It should be noted that, as stated in Section 8.6.4.1.3.1 or Section 8.6.4.1.3.2 for saw-toothed roofs, a pendent or upright sprinkler may be put up to 36 inches below the high point.

2.Provide calculations in accordance with Section 8.1.1(6) that show sprinklers installed with a higher deflector distance than required will still activate on time and operate similarly to sprinklers installed in line with NFPA 13 regulations.

Question #12 – New school building adjacent to existing

Can a new 17,000 sq ft autobody tech shop be built against an existing school without sprinkler protection?

No. Regardless of whether it falls within the definition of an E occupancy (Section 903.2.3 of the 2018 version of the IBC) or an S-1 occupancy (Section 903.2.9.1), the autobody tech shop must be sprinklered since it is larger than the 12,000-sf limit. According to IBC, Section 706, the sprinkler regulations would apply whether the structure was independent or divided from other buildings by a fire wall. Only the new addition would activate sprinklers in the current building, not the entire structure as a whole. Only the fire area for E and S-1 occupancies are subject to the requirement for sprinkler protection. This indicates that only the additional fire area must be sprinklered, but that fire area separation rules must also be adhered to. Fire barriers (IBC, Sections 707 and 707) are used to divide fire regions.3.10 calls for a 2-hour fire barrier between the new and the old. The sprinkler system protects a fire area without spreading into the existing structure thanks to the 2-hour fire barrier that divides the new addition from it.

Courtesy: Roland ASP, CET NFSA Technotes (Best of Sept 2021)