Question #1 – Standpipe Connections at Horizontal Exits The International Building Code (IBC) states in Section 905.4 that hose connections can be omitted from one side of a horizontal exit when it is located within 130 feet from a standpipe connection in the stairwell. NFPA 14, however, allows the hose connection to be omitted when it is located 200 feet from a standpipe connection in the stairwell. What are the applicable requirements for locating standpipe connections at horizontal exits?

According to NFPA 14 Section 7.3.2.2, hose connections must be placed on either side of a wall that is close to a horizontal exit’s exit aperture. When the travel distance is under 200 feet, Section 7.3.2.2.1 authorizes the removal of one hose connection on the opposite side.

While the term “adjacent” does not currently have a defined meaning, a Public Input 38-NFPA 14-2019 suggestion that was adopted at first draft calls for a hose connection at horizontal exits to be visible and within 20 feet of the exit in the 2023 edition.

The IBC is more stringent but also permits the removal of a horizontal hose connection if the next side of the horizontal exit is reached from a 30-foot hose stream from a nozzle attached to 100-feet of hose, linked to an interior exit stairway hose connection. To particularly address the decreased degree of firefighter protection provided by horizontal exits, the 130-foot restriction was altered in the code.

NFPA 14 would be superseded as a Standard by the IBC, making the minimum 130 feet.

The following provides justification for the 2006 IBC amendment’s exclusion for horizontal hose connections:

“According to the 100-foot hose arrangement with a 30-foot hose stream, the exemption added to Section 905.4(2) allows for a suitable placement of hose connections on a floor. The placement of stairways and horizontal exits next to one another is common in architectural designs. It is preferable to depart a stair enclosure with a charged fire line than it is to go inside a floor of a building to connect to a hose connection that is located at a horizontal exit. Given that under Section 905.4(6), the requirements for this exception’s placement of hose connections in the stairwells based on a 30-foot hose stream with 100 feet of hose are acceptable. The hose placed in a structure without a horizontal outlet may reach 150 to 200 feet.”

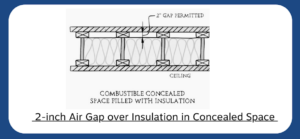

Question #2 – 2-inch Air Gap over Insulation in Concealed Space ?

Section 8.15.1.2.7 in the 2013 edition of NFPA 13 allows sprinklers to be omitted from combustible concealed spaces when filled with noncombustible insulation. The next section states that a 2-inch maximum air gap at the top of the space is allowed.

Is the maximum allowable air gap measured from:

* The top of the insulation to the bottom of the floor above. -or-

* From the top of the insulation to the bottom of the top cord of the wood floor truss

It is preferable to depart a stair enclosure with a charged fire line than it is to go inside a floor of a building to connect to a hose connection that is located at a horizontal exit. Given that under Section 905.4(6), the requirements for this exception’s placement of hose connections in the stairwells based on a 30-foot hose stream with 100 feet of hose are acceptable. The hose placed in a structure without a horizontal outlet may reach 150 to 200 feet.

Question #3 – Design Criteria for Group A Plastics stored between 5 ft. and 12 ft. in height Section 17.2.1.3 in the 2013 edition of NFPA 13 states that for storage of Group A plastics between 5 ft and 12-ft in height, the requirements for Extra Hazard systems would apply. Should the design criteria for Extra Hazard Group 1 (0.30 gpm/ft2 over 2500 sq. ft) or the criteria for Extra Hazard Group 2 (0.40 gpm/ft2 over 2500 sq. ft) be applied for this storage application?

Answer- No, that’s not the solution. The intent of Section 17.2.1.4 is not to relate to design criteria, but simply to installation requirements, such as sprinkler spacing and pipe types that may be employed. The density and area of application would be established according to Section 17.2.1.2.1, which indicates that they would be determined from “Figures 17.2.1.2.1(a) through Figure 17.2.1.2.1(f) depending on the actual arrangement.”

Following the determination of the design criteria (density and area), the installation specifications (sprinkler spacing, kinds of sprinklers) for additional hazard occupancies take effect.

Question #4 – Forward Flow Test for Antifreeze Loop Backflow Preventer Section 13.7.2.1 in the 2020 edition of NFPA 25 requires a forward flow test be performed on all backflow preventers installed in fire protection systems. It is understood that this requirement applies to the main backflow preventer protecting the municipal water system. Does this requirement also apply to the small backflow preventer installed in an antifreeze loop?

Yes, a forward flow test would be necessary before installing a backflow preventer on an antifreeze system. According to what is mentioned in this section, NFPA 25 mandates that every backflow preventer placed in a water-based fire prevention system pipe undergo an annual forward flow test.

The internal backflow check valves are put through their paces during the forward flow test to make sure they will completely open in the case of a fire and deliver the necessary flow rate for the system being served. This goal would apply to both the primary backflow preventer and the system supplied by the antifreeze loop.

To conduct the forward flow test, a valve is inserted after the backflow in Figure 8.6.3.3 of the antifreeze backflow installation in the NFPA 13, 2019 version.

Question #5 Draft Curtains and ESFR sprinklers NFPA 13 requires that ESFR sprinkler systems adjacent to sprinkler systems with standard response sprinklers to be separated with a draft curtain. A draft curtain is to be installed along bar joists for this purpose. Due to the configuration of the bar joist, there are small gaps in the draft curtain at the seams. Do these seams need to be sealed with fire caulk?

Answer-

No, as mentioned in the appendix to this part, NFPA 204, Standard for Smoke and Heat Venting, regulates draught curtains. Draught curtains are described by the 2019 version of NFPA 13 in part 3.3.57. Neither NFPA 13 nor NFPA 204 specify that draught curtains between ESFR and standard response sprinklers must be sealed with fire caulk. A draught curtain is not a fire-rated or fire-resistive element that needs to be sealed in accordance with building or fire rules.The following quote from NFPA 204, Section A.7.1, provides some helpful advice: “A draught curtain is designed to be generally smoke-tight. A draught curtain’s purpose is to block the entrained smoke and ceiling jet created by a structure fire.

Question #6 - Virtual Reality/Gaming Pods A video arcade store is being provided with a NFPA 13 fire sprinkler system. This arcade includes fully enclosed virtual reality and video game “structures.” There does not seem to be an allowance in NFPA 13 to omit sprinklers in these spaces. Section 8.1.1 in the 2016 edition of NFPA 13 does allow sprinklers to be omitted from furniture that is not intended for occupancy. As people are intended to occupy these arcade “enclosures,” it does not appear that this section would apply. Are sprinklers required in these arcade “enclosures”?

Most likely not, and the 2022 version contains a new section that seems to deal with this circumstance. The new “Small Temporarily Occupied Enclosures” section 9.2.10 permits sprinklers to be deleted from small, isolated temporary inhabited enclosures that:

- Don’t reach the ceiling

- do not include storage

- No more than 24 square feet.

The stated places appear to fit these requirements, even though this part was meant for areas like lactation rooms, phone booths, pods, or booths for hearing tests. The equivalence clause (Section 1.5 of NFPA 13) may be used by the Authority Having Jurisdiction to permit the adoption of this section beginning with the 2022 edition of NFPA 13.

Question #7 – Required Hanger Locations on Armover Piping Section 9.2.3.5 in the 2016 edition of NFPA 13 is titled “Unsupported Armover Length” and allows a 1-in. armover pipe without a hanger to be up to 24 in., OR, for pendent sprinkler below ceiling over 100 psi to be up to 12 in. Can an armover WITH a hanger, for 1-in. pipe, be up to 3 ft. in length between the hanger on the armover pipe and the sprinkler itself as allowed by Section 9.2.3.4.1? In other words, can the unsupported length Section 9.2.3.4 be applied to armovers?

Answer- No, there is a reason why these two requirements are in distinct parts of NFPA 13. With precise wording and illustrative visuals, Section 9.2.3.4 is written to only apply to the ‘…end sprinkler and the final hanger on the line…” If a continuous section of pipe is being placed, the “line” is meant to refer to a branch line, and the hanger is supporting the weight of the cantilevered pipe.

The 1 in. pipe can cantilever in this situation 3 feet from the final hanger. For movers that are made up of numerous fittings and short sections of pipe, see Section 9.2.3.5. The standard restricts these assemblies to a cumulative horizontal length of 24 inches before a hanger is needed since they cannot support the same weight as a cantilevered pipe in the aforementioned area. Armovers are frequently made of smaller-diameter pipes, however unlike in 9.2.3.4, the hanger distance is not affected by pipe diameter.

Question #8 – Dry Pipe System Size A dry pipe system has a system volume of 980 gallons. On a system this size (over 750-gallon capacity), is it a requirement of the 2019 edition of NFPA 13 to have a water delivery time of 60 seconds or less?

Answer-There is no simple yes or no response to this. One of two techniques must be used, according to NFPA 13, for dry systems larger than 750 gallons:

- As long as the initial water release to the ITC happens in 60 seconds or less, NFPA 13 permits exceeding the 750 gallon capacity. This is described in NFPA 13, Section 8.2.3.2 of the 2019 Edition.

- When water supply is computed using one of the stated calculation methods or initial water discharge is confirmed by an adequately sized test manifold, the volume restriction may be exceeded. Both Sections 8.2.3.5 and 8.2.3.7 discuss these circumstances. If this choice (as opposed to option #1) is selected as the mechanism for water delivery time, Table 8.2.3.6.1 will be applicable.

The NFPA 13 Handbook continues, “this test connection is piped from the most distant branch line at the highest elevation of that branch line,” in reference to condition #1. The time period begins when the valve is fully opened and ends when water is first discharged. A continuous trickle of water is not necessary, but it should start pouring from the ITC within the allotted 60 seconds, it continues.

Question #9 – Sprinkler Omission Above Indoor Swimming Pools A new indoor pool facility for the local high school is being installed. The building includes a pool and locker rooms, bathrooms, storage and office areas. There is concern about being able to maintain the sprinkler system (mainly the sprinklers) located over the pool as they are roughly 30 feet above the pool deck and will be difficult to reach over the pool area. (A code review page and plans were provided) Does Section 507.4 of the International Building Code (or other provision of the code) allow the automatic fire sprinkler system to be omitted from the pool area?

Fire Sprinklers over the pool area may not be used in A-4 occupations, such as indoor swimming pools, according to the IBC. The section 507 specifies requirements for constructions with an infinite amount of space. In particular, Section 507.4 calls for an NFPA 13 system and allows sprinklers above the pool area; however, the project must meet a number of requirements in Section 507 in order to be granted this exception. According to the given code review page, the following problems prevent the project from being eligible for the sprinkler exception:

- 507.1 permits an infinite A-4 space, however this proposal contains what would count as a storey in the basement.

- The A-4 is permitted to have an infinite area under sections 507.1.1 and 507.4, but not as a mixed-use structure. Buildings with an infinite area may have accessory occupancies as long as they don’t take up more than 10% of the total A-4 space.

- The A-4 may have an unrestricted space with side yards that are 60 feet or longer encircling the structure under Sections 507.2 and 507.4. If this structure has side yards of 60 feet, it is unclear.

- Sprinklers over the pool area may only be turned off under the following conditions:

- doors that lead immediately outside. It is unclear whether this exception is satisfied.

- system for manual pull stations on fire alarms. It is unclear whether this exception is satisfied.

Fire sprinklers must be installed in each room of the structure, according to NFPA 13’s Section 8.1.1(1). Spaces over swimming pools are not an exception. Pool covers are frequently bought by owners so that the area above the water may be used for other things. A pool cover is put over the pool and the area is used for a dance, for instance, in the opening scene of the film “It’s a Wonderful Life”. The pool may occasionally be emptied and utilised for a number of different things even if a cover is not used.

According to NFPA 25, sprinkler inspections are performed from the ground up. There isn’t much of an incentive or need to physically approach the sprinkler other from an activation.

Question #10 – Exterior Bathroom in NFPA 13D A single-family house is being equipped with a residential sprinkler system in accordance with NFPA 13D. There is a bathroom (over 55 sq ft) that will serve the outside pool. This bathroom is attached to the house but does not have a door or unprotected opening into the dwelling. Are sprinklers required in this bathroom?

Answer- Yes, sprinkler protection would be necessary in a bathroom larger than 55 square feet based on the prescriptive standards of NFPA 13D, even if there are no exposed openings into the dwelling unit.

Sprinklers must be put in all locations, with the exception of those where a particular provision permits sprinklers to be removed, according to provision 8.3.1 (in the 2019 version with similar language in prior editions). There is no clause that would permit the bathroom depicted to lack sprinkler protection.

Although this section is specific to exterior closets and closets in garages, it cannot be expanded (at least prescriptively) to include bathrooms that do not open to a dwelling unit. However, Section 8.3.8 does allow sprinklers to be omitted from exterior closets that do not have unprotected openings into the dwelling unit.

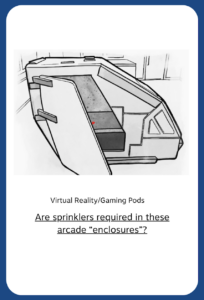

Question #11 – Connection for Anti-vortex Plate The handbook of NFPA 20 shows a long turn elbow connected to the anti-vortex plate with a welded connection. Is it permitted for the long turn radius pipe to be connected to the anti-vortex plate with a flanged coupling or must it be welded?

Yes, a flange can be used in place of a welded connection to attach the antivortex plate to the long turn elbow.

According to NFPA 20, 2019 edition, Section 4.16.10, the discharge outlet of a tank utilised as the suction source for a fire pump must be fitted with an assembly that regulates vortex flow in line with NFPA 22. Every suction tank’s discharge outlet needs to have an anti-vortex plate assembly, according to NFPA 22, 2018 edition, Section 14.2.13 for the anti-vortex plate assembly. The assembly must include a long radius elbow fitting, if necessary, positioned at the outlet at a height above the tank’s bottom that is equivalent to one-half the diameter of the discharge pipe, and a horizontal steel plate that is at least twice the outlet’s diameter. The minimal height above the tank’s bottom is 6 inches.

The connecting technique for the elbow’s anti-vortex plate is not specifically addressed in the standard itself, as was already mentioned. While not a requirement of the standard, the annexe explanatory information in Section A.14.2.13 and Figures B.1(p)(q) suggests the usage of a welded long turn elbow.

For the low to negative pressures related to the suction side of the fire pump, the usage of a coupling with a rubber gasket might not be acceptable.

Question #12 – Minimum Flowrate for Fire Pump Performance Testing During acceptance testing of a 2,500 gpm rated fire pump, the test was stopped at 2,800 gpm due to a low suction pressure (5 psi). The water source is a city water main. On this system, the maximum demand of the fire sprinkler system is 2,163 gpm. The AHJ stated that the pump must be tested at 150% of rated capacity. In accordance with the 2013 edition of NFPA 20, is testing beyond 100% of rated flow required?

Answer- No, the pump is not required to be tested at 150% of its rated capacity for fire pump acceptance testing.

In the 2013 edition of NFPA 20, Section 4.6 for the water supply source, Section 4.6.2.3.1 states that the water supply shall be deemed adequate if it can provide the greater of 100 percent of the pump’s rated flow or the maximum flow demand of the fire protection system(s) when the maximum flow available from the water supply cannot provide a flow of 150 percent of the pump’s rated flow.

Both the 2,500 gpm rated fire pump flow and the 2,163 gpm maximum system demand must be met by the water supply for this system.

For field acceptance testing and fire pump flow testing, Section 14.2.6.2.6 states that the fire pump shall be operated at the greater of 100 percent of rated flow or the maximum flow demand of the fire protection system(s) maximum allowable discharge to determine its acceptance where the maximum flow available from the water supply cannot provide a flow of 150 percent of the pump’s rated flow.

According to Section 14.2.6.2.6.1, this decreased capacity should be considered a valid test, provided that the pump discharge exceeds the flow rate and design of the fire prevention system. The fire pump in this instance must pass an acceptance test at 2,500 gpm. This is equal to either 100% of the rated flow (2,500 gpm) or, as specified by the standard, the maximum flow demand of the fire prevention system(s) (2,153 gpm).

Courtesy: Roland ASP, CET NFSA Technotes (Best of March 2022)