The foundation of many activities are industrial vehicles and equipment. These workhorses, which range from forklifts, Skid steers, Loaders, Excavators to large machinery clearing building sites, keep our industries moving. More often we ignore fire safety that is a vital component. Because industrial vehicles and equipment combine:

- Flammable fluids: Combustible materials are found in fuel tanks, hydraulic systems and engines.

- Electrical parts: Materials nearby can catch fire from sparks from defective wiring or hot batteries.

- Hot surfaces: The considerable heat that engines and exhaust systems produce could set off nearby objects.

- Dust buildup and friction: Sparks or spontaneous combustion can occur in dusty settings or moving parts.

These elements demand that industrial equipment’s and vehicles have fire safety given top priority. The rules and best procedures to maintain the safety of your fleet and avoid fire situations will be covered in detail in this article.

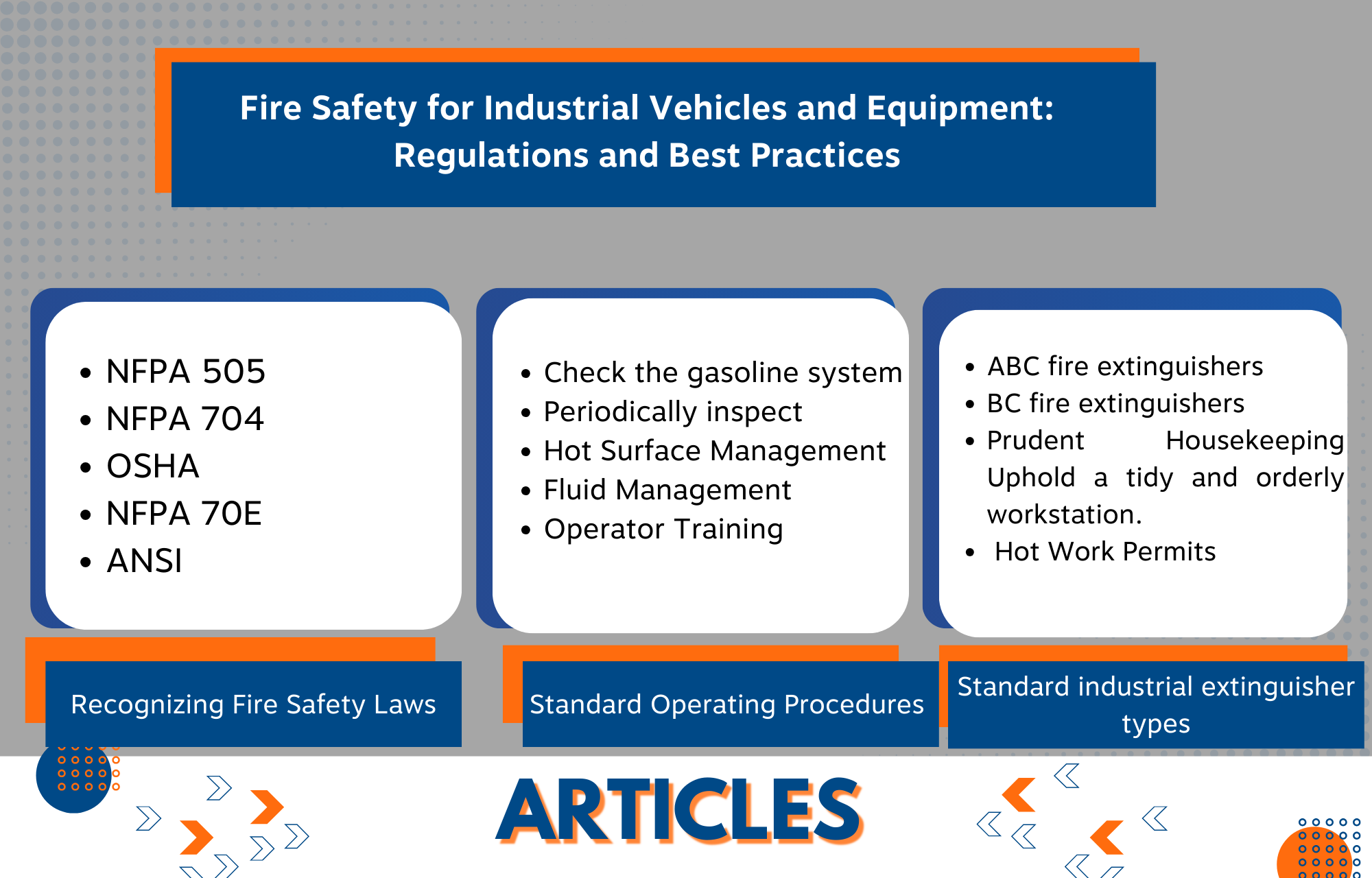

Recognizing Fire Safety Laws

The equipment’s and vehicles deployed in the industry it works in, and your local authority having jurisdiction (AHJ) all affect the fire safety rules for industrial equipment’s and vehicles.

The National Fire Protection Association (NFPA) is a publisher of several regulations and standards pertaining to industrial fire safety, such as:

NFPA 505: To reduce the possibility of fires and explosions and hence avoid property damage and fatalities, this standard offers fire safety recommendations for powered industrial trucks (PITs).

NFPA 704: This technique facilitates the fast and easy communication of the risks by using a color-coded diamond to show the health, flammability, and reactivity hazards of substances.

OSHA: OSHA has rules addressing fire protection in workplaces, including requirements for portable fire extinguishers, emergency exits, and volatile liquid storage.

NFPA 70E: This standard deals with workplace electrical safety and offers instructions for shielding employees from electrical risks, including arc flash and arc blast.

ANSI: The safety standards that ANSI creates for various industrial equipment categories frequently take fire safety into account.

Maintaining workplace safety and staying out of serious legal trouble depend on following these rules. To fully grasp relevant fire safety criteria, it is best to refer to industry-specific rules and your local AHJ.

Standard Operating Procedures for Industrial Vehicle and Equipment Fire Safety

These are the main actions you may take to reduce the possibility of fire and encourage safe operation:

- Plan regular preventive maintenance for your equipment and fleet. These covers looking for leaks, replacing worn-out belts, hoses, and filters, and making sure the engine is properly lubricated.

- Check the gasoline system carefully for leaks, cracks, and loose connections. Around fuel tanks and refilling locations, make sure there is enough ventilation.

- Periodically inspect your equipment’s and vehicles electrical wiring often for damage or overheating symptoms. Quick resolution of any electrical problems will help to avoid sparking and possible fires.

- Hot Surface Management: Keep up adequate engine cooling systems and make sure exhaust systems are clean and operating as they should.

- Fluid Management: Keep lubricants, oils and other combustible fluids in special, appropriately labelled containers. Waste fluids properly.

- Operator Training: Educate your operators in fire safety protocols, which include spotting any fire threats, using fire extinguishers correctly, and safely getting out of a burning

- Fire Extinguisher Selection and Location: Make sure your equipment and fleet have the right rated fire extinguishers, and that they are easily accessible and routinely checked.

- Standard industrial extinguisher types include:

ABC fire extinguishers: Work well against many types of fires (class A: common combustibles, class B: combustible liquids, class C: electrical)

BC fire extinguishers: For use on gas and liquid fires.

- Prudent Housekeeping Uphold a tidy and orderly workstation. Remove any overabundance of flammable materials, dust, or debris from surrounding machinery and vehicles.

- Hot Work Permits: Any hot work—welding, cutting, grinding—that involves vehicles or equipment should be subject to a permission system. Before starting hot work, have the necessary fire safety precautions in place.

Your Industrial Fire Safety Partner is Rotaflow Fire & Utility

- Compliance: Rotaflow Fire & Utility subject matter experts are trained to identify, and trouble shoot fire safety issues that industrial businesses encounter. Our extensive service offering will enable you to maintain the safety and compliance of your fleet with fire safety laws.

- Fire Safety Inspections: Our skilled professionals thoroughly inspect your industrial vehicles and equipment, once the inspections are performed our technicians would recommend solutions to fix the issue.

- Fire Extinguisher Services: We ensure your extinguishers are ready for use right away in an emergency by offering services for selecting, installing, inspecting, and maintaining them.

- Training: Our subject matter experts provide customized fire safety training programs encompassing fire prevention techniques, extinguisher use, and emergency evacuation strategies are available for your operators.

- Industrial Fire Prevention Systems: We can design and install specialist fire prevention systems for places where industrial vehicles and equipment operate based on the task to be performed.

- Working with Rotaflow Fire & Utility means you get a devoted group of people who are concerned about maintaining the safety of your industrial setting. As part of our commitment,

- Qualifications and Experience: Our Team consists of licensed fire safety experts with a wealth of industry experience. We keep ourselves current with the most recent best practices and fire safety regulations.

- All your industrial fire safety needs may be met with our comprehensive variety of services, which include everything from system installation and extinguisher maintenance to inspections and training.

- Customised Plan: We are aware that every operation has different requirements. We spend our time learning about your requirements and customise our fire safety plan that meets and exceeds your expectations.

- We think that being proactive is essential. Before fire hazards become emergencies, we want to identify and mitigate them

- Safety is our first concern. Our commitment is to assist you in providing your staff with a secure workplace.

Putting money into fire safety protects lives and your most valuable possessions, and it also complies with regulations. Work with Rotaflow Fire & Utility to guarantee the safe and effective operation of your industrial vehicles and equipment, therefore reducing the possibility of expensive downtime and fire emergencies.

Get in touch with Rotaflow Fire & Utility right now to arrange for an industrial vehicle and equipment fire safety assessment. Together, let us design a safer future for your business.

Courtesy: Reji Mathews, Materials Manager, Procurement, Fabrication, Weights & Measurements