When retrofitting standpipes and sprinklers into old structures, the center open space of the steps is frequently employed. All standpipes must adhere to NFPA 14's Section 6.1.2's criteria for pipe safeguards. Unless otherwise approved by the body with jurisdiction, hose connections must be provided at the intermediate floor landing. For NFPA 13D systems, fire department connections (FDCs) are optional but can be installed at the owner's desire. FDCs must be placed such that hose lines may be linked to the inlets without being impeded by neighboring objects, be recognisable within 50 feet of a fire department access point, and be within 100 feet of a fire hydrant.

The 2019 edition of NFPA 13 Standard for the Installation of Sprinkler Systems does have requirements for sprinkler FDC locations found in Section 16.12.5 Arrangements. NFPA 14 states that standpipe systems in separate buildings or structures fed by the same water supply are not required to be interconnected. Fire department connection (FDC) sizing is required to include one 2 1/2 inch inlet for every 250 gpm. System type, demand pressure greater than 150psi, and combined system must be marked with ``STANDPIPE AND AUTOSPKR`` with 1-inch letters. Signage must include the pressure required to provide system demand of the standpipe system when greater than 150psi, and manual standpipes must be identified by signage at the FDC.

Class II standpipes installed under the 1978 edition of NFPA 14 must provide 100 gpm for at least 30 minutes at a residual pressure of 65 psi. All pressure-reducing valves must be inspected, tested, and flow tested every five years. Intermittent landing installation with AHJ or fire code official approval is allowed.

The 2021 International Building Code (IBC) requires Class I hose valve locations in every interior exit stairway at the main floor landing unless approved by the fire code official. Standpipe systems are allowed to be combined or independently supplied directly from the feed main. Plastic caps are allowed to be used to protect hose-connections threads on a standpipe connection and are not considered a deficiency per NFPA 25. The NFPA 14 technical committee is considering adding weep holes to caps. NFPA 25 requires caps to be inspected and replaced if missing/damaged or have missing/deteriorating gaskets.

HORIZONTAL EXIT HOSE VALVE LOCATIONS

According to NFPA 14 Section 7.3.2.2, hose connections must be placed on either side of a wall that is close to a horizontal exit’s exit aperture. When the travel distance is under 200 feet, Section 7.3.2.2.1 authorizes the removal of one hose connection on the opposite side.

Although the term “adjacent” is not currently defined, the 2023 edition has a revision that, if adopted, will mandate that hose connections at horizontal exits be visible and within 20 feet of the exit.

Although more stringent, the International Building Code (IBC) also permits the removal of a horizontal hose connection when the adjacent side of the horizontal exit can be reached by a 30-foot hose stream from a nozzle attached to 100 feet of hose, connected to an interior exit stairway hose connection.

SUPERVISORY AIR ON DRY SYSTEMS

The specifications for supervisory air included in Chapter 5 of NFPA 14 were taken from NFPA 13 Standard for Sprinkler Installation and apply to dry valves installed on standpipe systems.The technical committee is attempting to clarify these criteria in the NFPA 14 edition due out in 2023 after they proved to be rather ambiguous for multiple cycles of the standard.

This section will be clarified in the NFPA 2023 edition with new guidelines for supervisory air on all dry systems. The technical committee adopted a position that would call for every manual dry standpipe to be under air supervision.

Note: Temporary supervisory air on a dry system must meet the standards of NFPA 241 Standard for the Safeguarding of Construction, Alteration, and Demolition Operations.

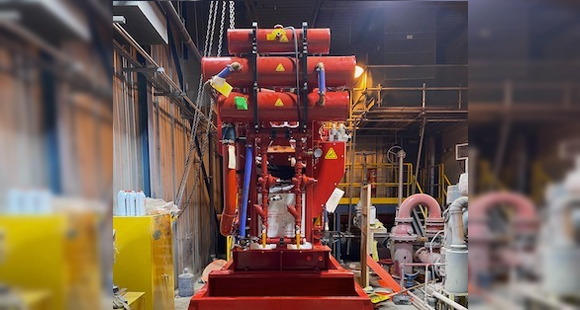

PIPE PROTECTION AND INSTALLATION OF STANDPIPES IN VERTICAL CENTER SHAFT OF STAIRS

The installation of standpipes (risers) in stairs is not subject to any particular site criteria in the NFPA 14 Standard for the Installation of Standpipe and Hose Systems, nor is hanging a standpipe (riser) in the vertical centre shaft area prohibited.

As it provides a channel of least resistance, the centre open space of steps is frequently employed for retrofitting older buildings with standpipes and sprinklers. When it comes to pipe arrangements that satisfy the needs for protection, hanging, and hose valve positions, this application does provide some challenges.

All standpipes must adhere to the pipe protection standards outlined in NFPA 14’s 2019 edition’s Section 6.1.2 Protection of Aboveground Piping. Hose connections must be provided at the intermediate floor landing (Section 7.3.2), unless the authority in charge (Section 7.3.2.1) authorises installation at the main landing of the evacuation stairs.

INTERCONNECTING STANDPIPES

The purpose of NFPA 14 Standard for the Installation of Standpipe and Hose System, Section 7.5 is to mandate the interconnection of every standpipe inside of a single structure. Meeting other standards is a criterion for being near to the supply.

As an illustration, all standpipes must have control valves that enable the isolation of each system, as well as a fire department connection (FDC) on the system side of the isolation valve. It is also necessary to install the isolation control valves between the water supply and the system’s initial hose connection.

Buildings or structures that are divided by horizontal or vertical firewalls are regarded as independent buildings and are exempt from the need to be interconnected as stated in the standard’s annexe.

It is not necessary to link standpipe systems in different buildings or structures that are supplied with water from the same source.

For instance, a building could have a wet standpipe system that is automatically activated, while a nearby parking garage may have a dry standpipe system that is automatically activated and supplied by the same fire pump and water main. Since they are protecting distinct structures, there is no requirement that these two standpipe systems be linked.

GENERAL FIRE DEPARTMENT CONNECTION QUESTIONS

Is a fire department connection necessary for NFPA 13D systems? is a frequently asked question. NFPA 13D sprinkler systems are not needed to have fire department connections (FDC). The 2019 NFPA 13D Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes has an annexe that explains this. FDCs are optional for NFPA 13D systems, according to the annexe, however they may be installed at the owner’s desire. Hydrostatic testing in line with NFPA 13 specifications are required if an FDC is installed.

The typical site criteria for fire department connections are another frequent query: In order to ensure that hose lines can be attached to the inlets without being obstructed by nearby objects such as buildings, fences, posts, landscaping, vehicles, or other fire department connections, the installation standards stipulate that FDCs must be located within 100 feet of a fire hydrant, be clearly visible within 50 feet of a fire department access point, and be arranged so that they are visible within 50 feet of a fire department access point.

The Section 16.12.5 Arrangements of NFPA 13 Standard for the Installation of Sprinkler Systems, 2019 version, does provide regulations for sprinkler FDC placements.

SIZING OF FIRE DEPARTMENT CONNECTIONS

In NFPA 14, Section 7.12.3, the requirement for fire department connection (FDC) size is stated. According to this regulation, FDCs must be sized to have a 2 1/2-inch inlet for every 250 gpm. This implies that five inlets measuring 2 1/2 inches would be required if the design calls for 1250 gpm.

FIRE DEPARTMENT CONNECTION SIGNAGE REQUIREMENTS

According to the requirements, a fire department connection (FDC) must have three things. Additional local adjusted regulations are frequently present and may also need to be taken into account.

1.System type, includes the manual wet or dry standpipe configuration.

- higher than 150 psi of system demand pressure

- When an FDC only provides maintenance for a piece of a building or a group of buildings

- A fire department connection that supplies standpipe and automated fire sprinkler systems must be identified as a combined system. In 1-inch letters, write “STANDPIPE AND AUTOSPKR” or “AUTOSPKR AND STANDPIPE”.

Additionally, signs must reflect the pressure needed to meet standpipe system demand when it is higher than 150 psi. 6.4.5.2.2 and 6.4.5.2.2.1 of NFPA 14

At the FDC, manual standpipes that are “wet” or “dry” must also be marked with signs. (NFPA 14, Section 6.4.5.2, 2019)

FLOW REQUIREMENTS FOR 1978 CLASS II STANDPIPES

According to the 1978 edition of the NFPA 14 Standard for the Installation of Standpipes and Hose Systems, Class II standpipes installed under that edition would need to deliver 100 gpm for a minimum of 30 minutes at a residual pressure of 65 psi at the topmost outlet of each standpipe with 100 gpm flowing (1978 NFPA 14 Section 5-4.1).

According to the NFPA 25 Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems, the system demand must be based on design criteria in force at the time of installation for performing the obligatory 5-year flow test of Class II standpipes.

*According to Chapter 13, all pressure-reducing valves and pressure-restricting devices on hose valves must be examined, tested, and maintained. Every five years, they must also undergo flow testing.

HOSE CONNECTIONS AT EXIT OR INTERMITTENT LANDINGS

Standpipes must be built at each main floor landing of the necessary evacuation stairs, according to the NFPA 14 Standard for the Installation of Standpipe and Hose Systems.

Although hose connections must be made at the main floor landing, the International Building Code (IBC) and NFPA 14 Standard for the Installation of Standpipe and Hose Stations both allow for intermittent landing installation with AHJ or fire code official clearance.

According to NFPA 14, needed exit staircases must have hose connections at each main floor landing. The authority having jurisdiction (AHJ) may order them to be built at the highest intermediate floor landings between floor levels, which is an exception to the requirement in Section 7.3.2.1 (7.3.2.1.1*).

Section 905.4 Location of Class I standpipe Hose Connection sub section (1) contains the criteria for Class I hose valve positions as stated in the 2021 International Building Code (IBC). Unless otherwise permitted by the fire code official, the IBC mandates hose hookups in every interior exit stairway at the main floor landing.

For operational usage and tactical coordination, the best hose valve placement should be determined in consultation with the fire department.

COMBINED SYSTEM

Standpipe systems may be connected together or fed separately directly from the feed main. Water is supplied to one or more standpipes or sprinkler systems via feed mains.

Combined systems are permitted to share the water feeding both the standpipe and sprinkler systems with the standpipe providing the sprinkler system and must be sized in compliance with NFPA 14 Section 7.6.

Hose connections are permitted under NFPA 13 Standard for the Installation of Sprinkler Systems, however when a standpipe is needed to comply with NFPA 14, it cannot be provided by the sprinkler system itself.

HOSE CONNECTION THREAD PROTECTION

To cover the threads of a standpipe connection, lastic caps are permitted by NFPA 14 and are not regarded as deficiencies by NFPA 25.

The NFPA 14 Standard for the Installation of Standpipes and Hose Systems simply calls for caps to protect the hose threads; it makes no mention of their intended function. Even if the local authority with jurisdiction (AHJ) mandated that the caps be made of metal (brass) during installation, there would still be a risk of failure if the valve was to be charged with the cap on for unlisted brass caps. The NFPA 14 technical committee has talked about this matter and is thinking of putting weep holes in caps.

According to the NFPA 25 Standard for the Installation, Testing, and Maintenance of Water-Based Fire Protection Systems, caps must be examined and replaced if they are broken, missing, or lack gaskets. The sort of material used to make caps is not covered by the standard, therefore a plastic cap is not regarded as lacking in any way.

COURTESY: The NFSA’s public fire protection specialist Terin Hopkins wrote this issue of TechNotes.