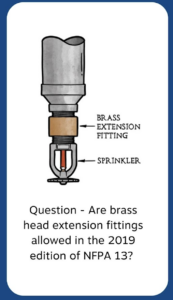

INTRODUCTION: NFPA 14 and NFPA 25 allow plastic caps to be used to protect hose connections threads on a standpipe connection, but they are not considered a deficiency. The International Building Code (IBC) requires standpipe hose connections in all interior exit stairways, which is defined by the building code. A plastic cap would be in violation of the local fire code, but not a deficiency covered by NFPA 25. NFPA 14 uses the term “required exit stair” to designate stairways that are required as part of the means of egress from a building and meet all the requirements for egress, including a location for the installation of standpipe hose connections. Section 9.3.4 of the 2016 edition of NFPA 13 applies to dry sidewall sprinklers in Seismic Design Categories C, D, E, and F, but exceptions exist to reduce or eliminate the annular (clearance) space around the sprinkler.

Question #1 – Minimum Orifice Size on Dry System Trip Test Connection

A single dry system includes both K-8.0 sprinklers and K-5.6 sprinklers. The dry system serves both an ordinary hazard loading dock which utilizes K-8.0 sprinklers and a light hazard office area with K-5.6 sprinklers. The most remote branch line (based on distance) is in the office whereas the most demanding sprinkler is in the dock. The inspectors test connection is in the office area off the most remote branchline.

Is it required to use an orifice equal to the smallest sprinkler (K-5.6) on the inspector’s test connection or would a K-8.0 sprinkler be acceptable?

An orifice with a K-5.6 or K-8.0 would be suitable.

In the installation guidelines, NFPA 13 does not actually refer to this connection as a “inspector’s test” connection. The term “trip test connection” is used by NFPA 13 since it better describes the connection’s function. It would be reasonable to infer that the orifice should be the same as the smallest orifice in the sprinkler system given that the connection is meant to replicate the opening of a single

sprinkler and that we typically test under “worst-case” scenarios. Even though many people believe it does, NFPA 13 does not actually state such.

In relation to dry-pipe systems, NFPA 13’s 2013 edition states in Section 8.17.4.3.1 that “A trip test connection or manifold not less than 1-in. in diameter, terminating in a smooth bore corrosion-resistant orifice, to provide flow equivalent to one sprinkler of a type installed on the particular system, shall be installed.” Similar sections can be found in earlier editions of the standard, dating back at least to 1983. The phrase “of a type installed on the particular system” enables the user to select any sprinkler orifice size that is employed in the system, not only the smallest one. Remember that this is not the case with wet pipe systems, which must include an alarm test connection (also known as an inspector’s test connection) that simulates the smallest sprinkler on the system.

A suggestion was made to amend the criterion such that the orifice simulates the smallest orifice on the system, similar to the requirement for wet pipe systems, during the preparation of the 2013 edition of NFPA 13. With the following justification, the committee rejected this proposal: “The intent of the standard is to allow the use of any orifice size on the system.”

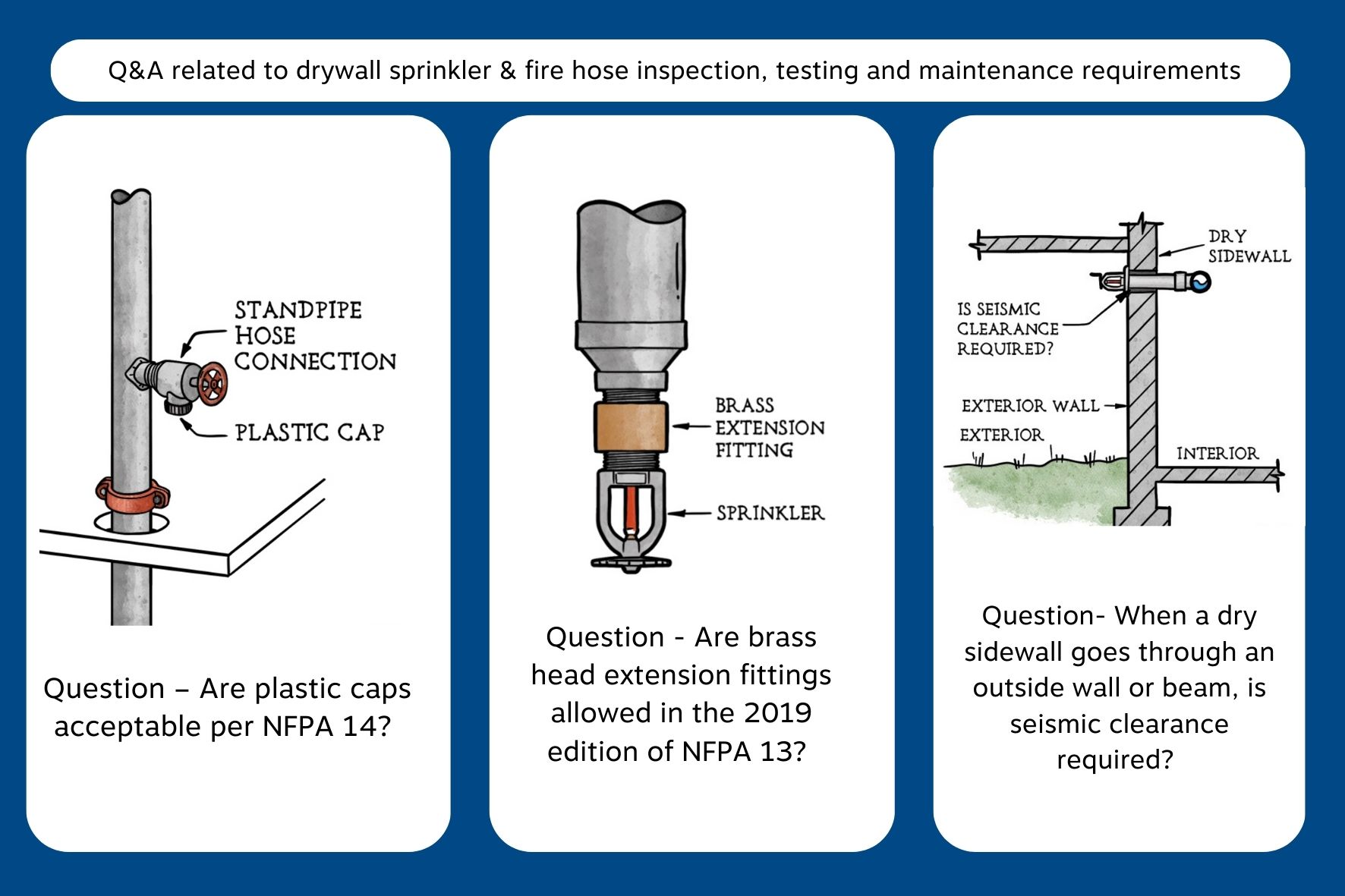

Question #2 – Plastic Hose Valve Caps

On a standpipe project, plastic caps were used on all hose valves. A service contractor performed a NFPA 25 inspection and sent the owner a letter stating that the plastic hose valve caps are a “deficiency” and need to be replaced with brass caps.

Three questions have been asked:

- Are plastic caps acceptable per NFPA 14?

- Would the use of plastic caps qualify as a deficiency?

- Theoretically would this qualify as a deficiency if brass caps are required locally by the AHJ?

To cover the threads of a standpipe connection, plastic caps are permitted by NFPA 14 and are not regarded as deficiencies by NFPA 25.

Only caps are required by NFPA 14, Standard for the Installation of Standpipes and Hose Systems, and no listing is necessary for this purpose.

In accordance with NFPA 25, Standard for the Installation, Testing, and Maintenance of Water-Based Fire Protection Systems, caps must be examined and replaced if they are broken, missing, or lack gaskets. The sort of material used to make caps is not covered by the standard, therefore a plastic cap is not regarded as lacking in any way.

A plastic cap would be in violation of the local fire code and enforceable by the fire code official but would not be a flaw covered by NFPA 25 if the authority having jurisdiction (AHJ) revised the local fire code to require brass caps on all standpipe hose connections.

Question #3 – Alternative to Flushing Underground Pipe

A 6-inch underground main has been installed from a water storage tank and continues underground to a fire pump room in an aircraft hangar. The underground contractor does not have water on site to flush the 16″ pipe per Section 10.10.2 of the 2016 edition of NFPA 24. The contractor has however ran a camera the length of the underground pipe and has confirmed that the pipe is clear of debris.

Is the method of using a camera an approved alternative to flushing the underground water main with water as part of the acceptance testing?

No. The NFPA 24 Standard for the Installation of Private Fire Service Mains and Their Appurtenances does not explicitly permit the use of a camera-based visual inspection in place of a flow test. When doing acceptance testing, NFPA 24 mandates a physical test (sometimes known as “flushing”).

According to NFPA 24, which was updated in 2016, underground pipe must be flushed at a minimum flow rate that is based on a velocity of 10 feet per second and is shown in Table 10.10.2.1.3. The necessary flow rate to flush this system would need to be determined because this table does not go up 16-inch pipe.

It should be noted that NFPA 20 would call for higher flows to clean this line because it is an underground conduit feeding a fire pump. This is mentioned in Annex Section A.10.10.2.1.3 of the 2016 version of NFPA 24, and the notion was introduced to the actual text of the standard in the 2022 edition. The NFPA 20 flushing flow rates are based on a velocity of around 15 ft/sec, which translates to a flow rate of 9,400 gpm for a 16-inch pipe. (See Table 14.1.1.1 of the NFPA 20 2019 version.)

When the water supply is unable to meet the requisite flows, NFPA 24 and NFPA 20 both permit a decreased flow rate. According to NFPA 20, the flushing flow rate must be at least 150 percent of the fire pump’s rated flow, and according to NFPA 24, the greatest flow rate that the system can handle in this situation is permissible. The maximum flow requirement of the fire protection system or, in cases when the 150 percent is not feasible, 100 percent of the fire pump’s rated flow, whichever is larger, would be considered an acceptable flow, according to NFPA 20.

“Water main swabbing” may be an effective substitute for flushing because it was stated that there is no water on the property. As an alternative to the flushing requirements, this idea was incorporated to the NFPA 24 2022 version. (See the updated Section 10.10.2.1.4). Swabbing is the process of introducing swabs (like polyurethane foam) into the pipe firmly in order to remove any material. This approach may be suitable in this case because it consumes far less water than conventional flushing.

Question #4 – Powder Coating Oven. Are ovens used to cure powder coating required to be protected with fire sprinklers in accordance with the 2016 edition of NFPA 13?

Are ovens used to cure powder coating required to be protected with fire sprinklers in accordance with the 2016 edition of NFPA 13?

The prescriptive requirements of the standard simply call for a study to be done to evaluate whether fixed or portable fire protection systems are needed for ovens, furnaces, or associated equipment, not that ovens must be sprinkler protected.

The 2016 version of NFPA 13’s Annex Section 22.16.2 does not have a requirement for sprinkler protection in ovens, and Section A.22.16.2.1 describes three circumstances in which sprinkler protection should be taken into account but does not include a requirement. Section 27.18 for ovens and furnaces in the NFPA 13 2022 version just makes a reference to NFPA 86.

A study must be carried out to evaluate if fixed or portable fire prevention systems are necessary for ovens, furnaces, or associated equipment, according to NFPA 86, 2019 edition, Section 9.1. Reviewing the fire risks connected to the equipment can help determine whether fire protection solutions are necessary. Fixed or mobile fire prevention systems must be offered when deemed required.

This standard addresses the protective requirements of ovens, furnaces, and associated equipment, according to Annex Section A.9.1. This standard does not include fire protection requirements that are not related to this device. The following factors determine the type and degree of fixed protection necessary:

- The design and layout of the oven, furnace, or other connected equipment

- the items going through processing

- Whether the fixtures or racks are flammable, are loaded too heavily with flammable finishing materials, or gather a significant amount of flammable drippings from finishing materials in the oven or ducting.

Although NFPA 86 compliance is mandated by NFPA 1, Section 51.1 of the 2021 version makes no mention of fixed fire prevention systems.

Please be aware that Section 3006 of the International Fire Code (IFC) 2021 edition does include requirements for the fire protection of industrial ovens under certain circumstances and may be evaluated for further advice.

Question #5 - Stairways for Standpipe Hose Valve Placement. In NFPA 14 and NFPA 101, what is the difference between a ``required stair``, ``required exit stair``, and ``non-required stair”.

In NFPA 14 and NFPA 101, what is the difference between a “required stair”, “required exit stair”, and “non-required stair”.

The International Building Code (IBC) stipulates where standpipe hose connections must be made. All interior escape stairways must have standpipe hose connections, as specified by the building code.

A protected path of egress travel to the exit discharge or public way is provided by an internal exit staircase, which serves to fulfil one or more means of egress design criteria, such as the required number of exits or exit access ravel distance. The NFPA 14 Standard for the Installation of Standpipe and Hose Systems refers to stairs utilised as part of the necessary protected means of evacuation from a structure when it uses the term “required exit stair.”

Although convenience stairs are permitted, the NFPA 101 Life Safety Code specifies the specifications for stairways utilised as a method of exit. In buildings with standpipe systems, a convenience stair does not function as a method of exit and is not subject to all egress standards or hose connection requirements.

When stairs are referred to as being “required,” it simply means that they must be included in a building’s means of evacuation and must satisfy all egress criteria, including having a place to put standpipe hose connections. Communication, open stairs, and convenience Installation of a standpipe hose connection wouldn’t be necessary if the stairs weren’t needed to comply with the building’s standards for a method of exit.

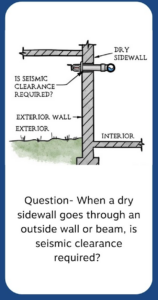

Question #6 – Extension Fittings- Are brass head extension fittings allowed in the 2019 edition of NFPA 13?

In line with Section 16.8.6 of the NFPA 13, 2019 edition, extension fittings are legal. As long as the internal diameter of the extension fitting has the same nominal intake diameter as the associated sprinkler, this section permits the installation of a single extension fitting up to 2-in without including it in the hydraulic calculations.

Only in mild and typical hazards would this rule apply to extension fittings used with K-8.0 and smaller sprinklers. For higher dimensional demands, installation of numerous (two or more) extension fittings would not be allowed.

Extension fittings with lengths more than 2 inches may be used if necessary provided they are clearly indicated. These expansion fittings would need to be accounted for in the hydraulic calculation, though.

Question #7 – Moveable Medical Record Storage

A hospital is being protected with a fire sprinkler system in accordance with the 2016 edition of NFPA 13. There is an area with moveable medical record shelf storage in the hospital.

Is there guidance in NFPA 13 to protect this type of shelving units?

Yes, the 2016 version of NFPA 13’s Section 20.6 offers recommendations for movable shelving unit sprinkler protection. For commodities consisting of paper files, periodicals, books, and similar materials to be categorised as light hazards, this section (20.6.1) covers transportable storage up to 8 ft in height. This section is meant to include “limited configurations of compact mobile storage units and materials,” as stated in 20.6.1.

Section 20.6.2, which stipulates that the top of storage must be at least 18 inches away from the sprinkler deflector, covers the crucial portion of Section 20.6. In an effort to establish design requirements for this unusual sort of storage layout, the Fire Protection Research Foundation conducted a study in which the NFSA took part. Since residential sprinklers and extended coverage sprinklers have larger, flatter spray patterns, NFSA decided it would be a good idea to try employing them to spray over the top of the units in a horizontal sidewall pattern. However, the makers of the tiny modular shelving units refused to permit any testing with a clearance less than 18 inches. They committed to constantly ensuring that their products would be utilised with at least 18 inches of clearance, and they also vowed to let their consumers know how crucial this criterion is.

Section 20.6 of NFPA 13 contains the findings of the FPRF study as well as the minimum 18-inch clearance needed to safeguard this storage (Section 20.6.2). The sprinkler deflector needs this area in order to create a spray pattern that covers the sprinkler’s protection area.

Question #8 – Temperature Rating of ESFR Sprinklers

Section 9.4.2.1 of the 2019 edition of NFPA 13 allows the use of intermediate-rated sprinklers in lieu of ordinary-rated sprinklers throughout a building.

Does this also apply to ESFR sprinklers?

If NFPA 13’s 2022 version is used, then yes.

According to Section 14.2.6 of the 2019 edition of NFPA 13, ESFR sprinklers must be ordinary temperature rated unless 9.4.2 specifies intermediate- or high-temperature ratings. According to this provision of the 2019 version of NFPA 13, conventional temperature sprinklers must be utilised unless there is a need to employ an intermediate temperature, such as the standards mentioned in provision 9.4.2.5.

In the 2022 edition, this section (14.2.6) was changed to read that ordinary or intermediate ESFR sprinklers may be utilised, unless Section 9.4.2 specifies the use of intermediate sprinklers. The latest version of NFPA 13 permits the use of either ordinary temperature or intermediate temperature ESFR sprinklers throughout an occupancy based on this changed language.

Sections 1.5 and 1.7 of the standard authorise the use of an upgraded version of NFPA 13. The authority having jurisdiction (AHJ) might be provided with this updated allowance to get permission to utilise intermediate-rated ESFR sprinklers.

Question #9 – Protecting Open Top Containers

An ESFR system for a warehouse is being designed. There is one area of the warehouse that has open-top containers.

As NFPA 13 does not allow ESFR sprinklers with open-top containers, the owner wants to know if a “top” can be placed on the container so that they are no longer considered to be “open-top” and if so, does NFPA provide any guidelines on the construction of the ‘top’?

It is possible to cover the container with a top to prevent it from being regarded as a “open-top” container. The NFPA 13, 2022 Section A.3.3.149 does offer four choices for how open-top containers may be addressed, however the NFPA does not offer any comprehensive recommendations on construction that may or should be utilised to cover the tops of the containers described.

- The first option is not applicable in this case.

- The second option directs you to set all open-top containers on the ground.

- The third option is to have apertures in the containers large enough such that the fluid enters and exits at the same flow rate and empties into the flue area.

- The fourth option is to firmly fasten flat or domed lids in racks over the open containers.

Option 4 indicates that open-top containers should not be used if “permanently affixed domed or flat lids in the racks directly over the open containers” are present. The engineer of record and AHJ should be contacted to decide the most cost-effective material to utilise as this section does not provide specific prescriptive design specifications of the lid.

Question #10 – Single-Family House connected to a Stable

There is a single-family house connecting to a caretaker’s unit and stable via an exterior covered walkway/breezeway. The applicable NFPA standards are the 2013 editions of NFPA 13 and NFPA 13D.

Could a single-family house connecting to the caretaker’s unit and stable via the exterior covered walkway / breezeway be designed with NFPA 13D? And the stable be designed with NFPA 13?

Yes, even if they are joined by a covered walkway, a single-family home might be protected as an NFPA 13D system with a neighbouring building housing a caretaker apartment and stable being protected as an NFPA 13 system.

Possible cause for worry is the need to safeguard the covered pathway. The connecting covered walkway would not need sprinkler protection for the NFPA 13D system connected to the single-family home. In covered, unheated building projections at entrances and exits, sprinklers are not necessary if the dwelling unit has alternate means of evacuation, according to NFPA 13D, 2013 version, Section 8.3.6. However, in order to comply with the requirements of this standard as applied to the stable building, it is necessary to evaluate NFPA 13, 2013 edition, Section 8.15.7 for external projects for the NFPA 13 system in the stable building.

Question #11 – Class II Standpipe Design in 1977- What flow and PSI was required for wet automatic Class II standpipe in a partially sprinkled building per NFPA 14 in 1977?

Over the years, local authorities frequently changed and adjusted the standards for the minimum pressure and flow of a Class II standpipe (1 12 in.). NFPA 14 does not contain any restrictions for pressure or flow, hence 1 12 in. hose connections were widely placed on fire sprinkler systems.

A minimum flow rate of 100 gpm and a minimum pressure of 65 psi have been required for new Class II hose connections built in accordance with NFPA 14 since the 1970s. The standards of a Class II system as established by NFPA 14 are not necessary for tiny hose connections (1 12 in.) to be put on a fire sprinkler system in accordance with NFPA 13.

Note: The authority having jurisdiction (AHJ) may choose to remove the hose/nozzle components of a class II standpipe in accordance with both the International Fire Code and the NFPA 1 Fire Code. This is permitted since Class II standpipes’ minimum flow rates fall short of the required minimum flow rates for structural firefighting.

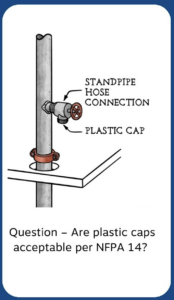

Question #12 – Dry Sidewall Clearance When a dry sidewall goes through an outside wall or beam, is seismic clearance required?

For dry sidewall sprinklers that reach through an outside wall and fall within Seismic Design Categories C, D, E and F, the seismic clearance criteria of Section 9.3.4 of the 2016 edition of NFPA 13 apply. To minimise or remove the annular (clearance) area surrounding the dry sidewall pipe, there are exceptions in Sections 9.3.4.3 through 9.3.4.7 and 9.3.4.10. For instance:

- The outside wall’s frangible design does away with clearance if it is not needed to be fire-rated.

- There is no requirement for clearance for dry barrel sprinklers with flexible hose.

- There is no need for clearance when rigid pipework is supported directly by structural beams.

Courtesy: Roland ASP, CET NFSA Technotes (Best of December 2021)