Modern sprinkler design comprises multiple responsibilities, including those of the estimator, project engineer, project manager, and quality control. The layout technician plays a crucial role. A layout technician’s profession might start with a high school diploma and lead to a key job in the fire sprinkler industry. With proper training and guidance, a new layout technician can become a valuable member of the team.

Successful fire sprinkler setup technicians must understand NFPA 13 and its criteria. This essay intends to provide a primer for layout technicians at the beginning of their careers or those interested in pursuing this rewarding sector.

At first sight, NFPA 13 can be intimidating. Breaking down the standard into smaller components makes it easier to understand. The 2022 edition of NFPA 13 has 32 chapters and six annex chapters.

Local ordinances and codes must comply with NFPA 13’s 32 chapters. The annex material is intended for informational purposes and cannot be enforced unless specifically accepted by the relevant authorities.

This assessment is subsequently forwarded to the layout technician. Although it is not a technician’s responsibility, understanding this stage is crucial for the layout and design process.

The danger level evaluation criteria are divided into two categories: storage and non-storage. Storage areas are further categorised into three different categories: Miscellaneous storage Low. Pile storage and high-piled storage. This essay focuses on fundamentals and will not go into detail about storage criteria.

Occupancy Classification

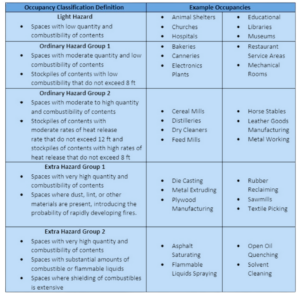

In the 2022 edition of NFPA 13, the design criteria for non-storage applications are grouped based on occupancy classifications (Chapter 4). NFPA 13 defines the occupancy classification, or hazard classification, depending on the level of fire hazard in a given location. This is not to be confused with the building code’s occupancy classification, which describes the space’s entire hazard, not only fire hazards. The NFPA 13 occupancy classifications are divided into categories. It’s worth noting that a building might have numerous classifications.

The table below explains each occupancy classification and includes examples of facilities that fall under each category. Annex Section 4.3 provides a comprehensive list of examples for each occupation.

Sprinkler Spacing

After determining the occupancy classification using the information in Chapter 4, sprinkler layout can begin. Sprinkler layout varies based on type (e.g., standard spray, extended coverage, or sidewall). This article will focus on the criteria for standard spray pendent and upright sprinklers, as outlined in Section 10.2. Chapter 10 defines the sprinkler spacing and coverage area based on the level of hazard. Sprinklers can be spaced wider apart for light hazard occupancies, while tighter spacing is required for ordinary and extra hazards. A summary of sprinkler spacing is provided in the table below.

- The maximum protection area varies according to construction and system type. Table 10.2.4.2.1(a) provides a detailed breakdown of protection areas for Light occupations.

The maximum protection area and sprinkler spacing vary depending on the system type Table 10.2.4.2.1(c) provides a detailed analysis of protection areas for Extra occupations.

The maximum protective area limits sprinkler spacing. For an ordinary occupancy classification, the maximum sprinkler spacing is 15 feet. Sprinklers set 15 feet apart in one direction are limited to 8 feet and 8 inches in the perpendicular direction to maintain a maximum protection area of 130 square feet. The “S X L rule” is used to determine the distance between sprinklers along branch lines, whereas L denotes the distance between sprinklers on neighbouring branch lines.

To meet the maximum protection area, multiplying the distance (S) by the distance (L) should not exceed the set limit. Additionally, sprinklers only cover half of the space (L or S) between them. As a result, the distance to walls is limited to half the distance in that direction (i.e., 1/2 S or 1/2L). For more detail contact Rotaflow team.

Obstructions

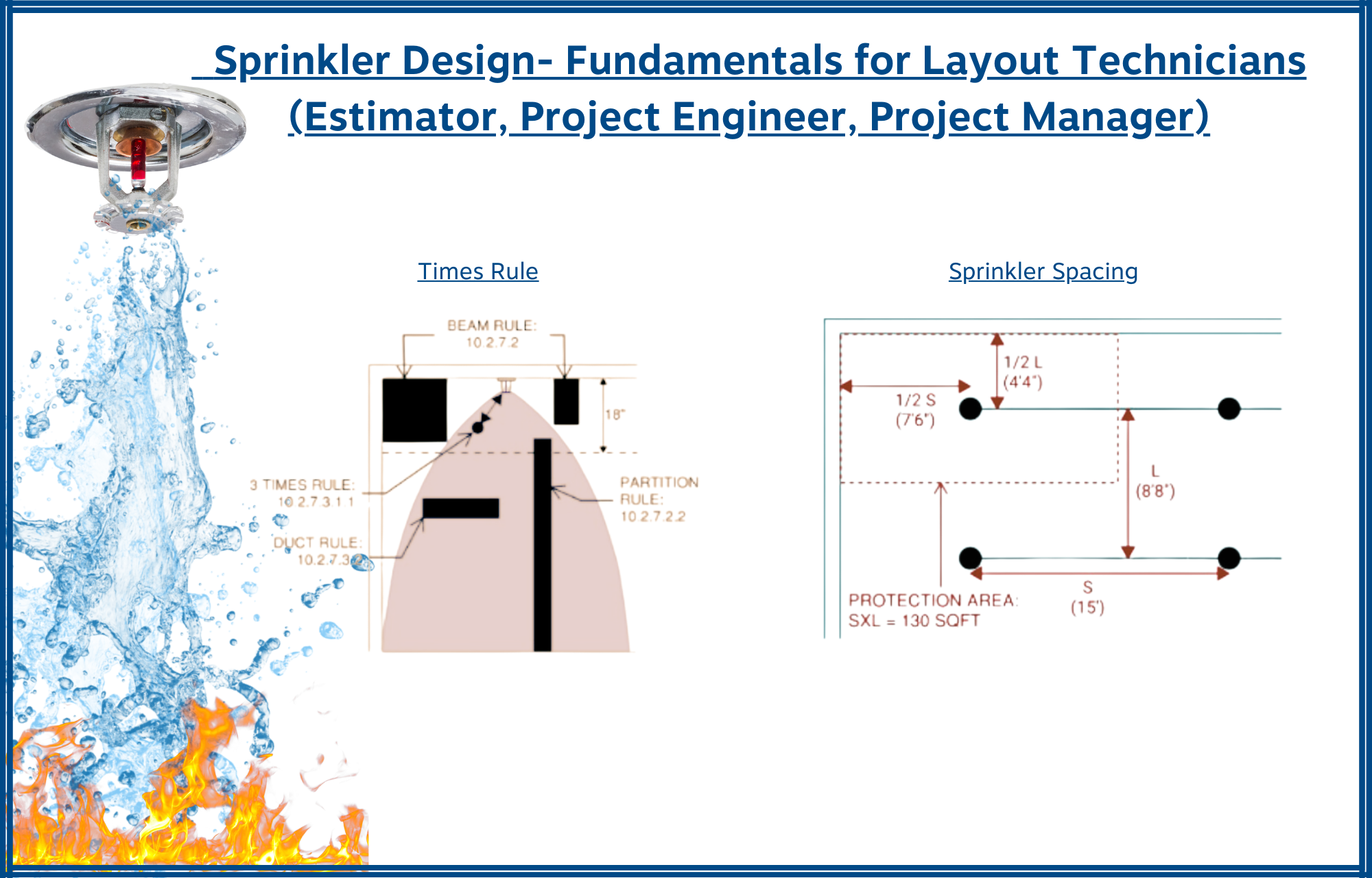

Sprinklers must be correctly spaced for adequate coverage, but obstructions such as objects or structural parts might hinder their effectiveness. NFPA 13 identifies these as obstacles. Obstructions near sprinklers have a greater impact on their performance. NFPA 13 distinguishes between two types of obstructions: those that hinder pattern development (18 inches below the sprinkler deflector) and those that prevent sprinkler discharge from reaching the hazard (18 inches or more below).

Beam Rule

To prevent pattern development impediments, spray over, under, or both sides of the obstruction. Section 10.2.7.2(1), along with Table and Figure 10.2.7.2(a), specifies the sprinkler’s position relative to an obstruction for spraying under it, sometimes known as the “beam rule.”. To effectively spray under an obstruction, the sprinkler should be spaced (A) away from the obstruction based on the maximum distance (B) the deflector is above the bottom of the obstruction.

3 Times Rule

As previously mentioned, there are two factors that can affect the degree of a blockage. Obstacles increase with size and proximity to the sprinkler. According to Section 10.2.7.3.1.3, sprinklers must be spaced at least three times the largest diameter of the blockage. This section is commonly known as the “3 Times Rule.”. This regulation is only applicable to horizontal impediments within 24 inches of the sprinkler and vertical impediments.

Obstructions can occur at any distance. Even in well-coordinated projects, appliances are often placed.

The lack of representation in plans makes it difficult to predict probable obstacles using the three-time rule. In light and ordinary hazard occupancies, the regulation only applies to structural elements. You can learn about it in Lunch and learn session with Rotaflow team.

Partition Rule (Suspended or Floor-mounted Vertical Obstructions)

If sprinklers cannot spray under or on both sides of an impediment, they can spray over it instead. In light hazard occupancies, as described in Section 10.2.7.3.2.1 and related figures and tables, the minimum distance (B) above an obstruction determines the distance (A) away from it. The partition rule is the inverse of the beam rule.

The 2022 edition provides guidelines on vertical obstacles in ordinary hazard occupancies (Section 10.2.7.3.2.3).

Wide Obstruction Rule

The three previous obstacle limitations only apply to things that are 18 inches below the sprinkler.

Obstructions located more than 18 inches below the sprinkler have less strict regulations. Sprinkler protection must extend to the area below fixed impediments over 4 feet wide, as per Section 10.2.7.4. The Duct Rule only applies to fixed impediments; thus, conference tables, for example, do not need sprinklers. This restriction does not apply to non-combustible impediments over 4 feet and less than 24 inches from the floor.

Sprinkler types, including sidewall, extended coverage, CMSA, and ESFR, have specific obstruction regulations outlined in their installation chapters.

Density/Area Method

Proper spacing and avoiding obstructions are ineffective if the sprinkler does not give enough water. The NFPA specifies the amount of water required based on the level of hazard. The table shows that controlling a fire in a location for spraying flammable liquids may require more water than in an office environment. Sprinkler density, defined in gallons per minute per square foot (gpm/sqft), determines the volume of water protection provided. Sprinklers must discharge liters of water per minute in per square foot of their protective area. For an Ordinary Group 2 (OH2) occupancy, the required density is 0.2 gpm/sqft. This implies that the sprinkler must spray at least 0.2 gallons of water per square foot every minute. In the example, the sprinkler in an OH2 occupancy protects an area of 10 feet by 13 feet, totaling 130 square feet. To calculate the minimal amount of water needed to discharge from this sprinkler, multiply the density (0.2 gpm/sqft) by the total area (130 sqft) to get 26 gallons.

NFPA 13 specifies both the minimum sprinkler density and the design area for calculating sprinkler flow. NFPA 13 uses the design area rather than an estimated fire size or testing results to determine the number of sprinklers required in a fire for a particular occupancy classification. Table 19.2.3.1.1 in NFPA 13 contains the densities and required areas of operation for each occupancy classification. A summary is provided below.

Conclusion

This article aims to cover the fundamentals for layout technicians, whether as a primer for beginners or a refresher for experienced technicians. This article discusses designing criteria for typical spray sprinklers using the density area application. Other types of sprinklers, including extended coverage, follow the same criteria as regular spray, but have differing spacing and obstruction rules. Sidewall sprinklers have a unique spray pattern and are positioned on the wall. NFPA 13 specifies Control Mode Specific Application (CMSA) and Early Suppression Fast Response (ESFR) sprinklers for storage applications. These sprinklers have different calculation, spacing, and obstruction requirements.

Courtesy: Jeff, P.E., Fire Protection Engineer for the NFSA.