Introduction

It’s official: TechNotes is now live! This is wonderful news for our members! This change is meant to make it easier, faster, and more interactive than ever to get to our technical insights.

The change has a number of benefits: emails are shorter, which makes them easier to deliver; you can access related tools, articles, and updates directly from our website; and all of your TechNotes resources and member perks are now in one place.

You can go to the new online TechNotes by logging in with your Association account. If you’re already registered, just keep going. If you’re new, click “New User” and sign up with the parent business that is linked to your work email address. When you log in, you’ll get the same reliable technical content, but in a more integrated way.

Thank you for your ongoing interest and support as we work to improve how you learn about fire safety. In this issue, we look at field inspections and how to properly place sprinklers. We talk about how following NFPA 13 and manufacturer guidelines for installation makes sure that the system works well and passes inspection.

Field Inspection: Sprinkler Positioning

Proper sprinkler arrangement during installation is critical—not just for optimum activation and operation, but also for a successful field inspection. This article examines the key factors that influence proper sprinkler positioning, emphasising technical requirements, best practices, and the importance of following manufacturer-published instructions when applicable—because positioning rules can be derived from NFPA 13, the manufacturer, or both.

Field Inspection for New Installations

When it comes to new fire sprinkler installations, it is critical to understand where the requirements to examine the work originate. While NFPA 13 specifies acceptance testing, it is not necessary that the installation be inspected prior to concealment. The necessity to evaluate the installation before ceilings or walls are completed stems mostly from model fire and building codes like the International Fire Code (IFC) and International Building Code (IBC). This is generally included as a requirement of the construction permit, emphasising the importance of inspections during the installation process to ensure compliance before systems are covered or placed in service.

IFC 109.3: Concealed work: It is the duty of the permit applicant to keep the work visible and accessible for inspection purposes.

What are Field Inspections?

When referring to field inspections for new installations, the phrase refers to on-site inspections performed to ensure that the system was installed in conformity with applicable codes and standards. These often involve a “rough inspection,” which is undertaken before any work is concealed to ensure correct layout, spacing, sprinkler positioning, material selection, and so on. Other types of inspections include acceptance tests, such as hydrostatic pressure tests, pneumatic tests for dry systems, and so on, as well as critical operational tests to guarantee system readiness, such as waterflow tests and trip tests. When it comes to sprinkler location, both rough and final checks are necessary to ensure appropriate installation.

Sprinkler Positioning

The sprinkler installation criteria in NFPA 13 are extensive and complex. Even if other critical installation components of NFPA 13 are ignored–design and discharge ideas, water supply, hanging and bracing standards, valve requirements, and so on–the sprinkler itself must be positioned to activate and disperse water in a reasonable manner. Let’s look at positioning with relation to deflector distances and orientation.

A satisfactory performance

NFPA 13 Section 9.1.1: (3) Sprinklers must be positioned and situated to ensure appropriate performance in terms of activation time and distribution.

The “Basic Requirements” of NFPA 13, Section 9.1.1, 2025 edition, provide a necessary framework for the overall system objectives. Section 9.1.1(3) states that sprinklers must be positioned to provide “satisfactory performance.” Sections 9.5.2-9.5.5 outline general regulations for all sprinklers and must be followed to attain this performance aim. The standard then adds sprinkler-specific standards in future chapters, such as Chapter 10, which covers typical pendant, upright, and sidewall sprinklers. The discussion that follows looks at the deflector location criteria for all sprinklers covered in Chapter 9.

Positioning Overview

With so many sprinklers to choose from, it makes sense to have a set of standards for all applications regarding location. This ensures a shared understanding when it comes to queries like “where do I measure from?” for deflector lengths and “how and when do I orient the sprinkler with the pitch of the ceiling?”

When attempting to achieve “satisfactory performance” in terms of activation time and water distribution, it is reasonable to set a limit on how far down a sprinkler can be installed below a ceiling or structure, as well as provide guidance on deflector orientation under sloped ceiling scenarios. While specific dimensions are provided for each sprinkler type in separate chapters, such as standard spray (Chapter 10) and extended coverage (Chapter 11), Section 9.5.4 tells us where to measure from when measuring from the building or ceiling to the deflector for all sprinklers.

As previously stated, the standard specifies maximum measurements based on structure and sprinkler type; but, during field installations, measuring from the structural deck or ceiling may not be acceptable, which is why Section 9.5.4 is so crucial in directing us where to measure from.

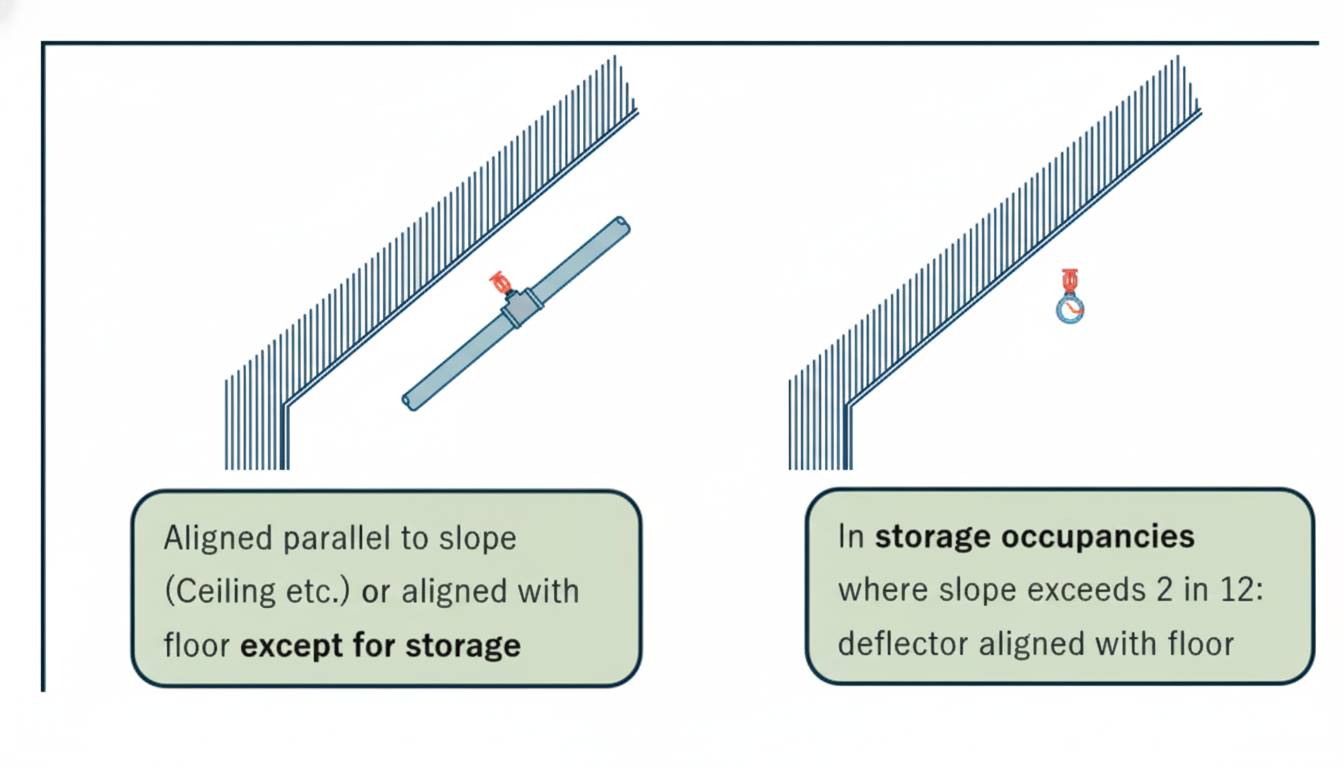

Corrugated metal deck roofing. The standard demands measuring from the bottom of the

corrugated surface; however, if the corrugated deck’s depth exceeds three inches, the measurement must be taken from the high point.

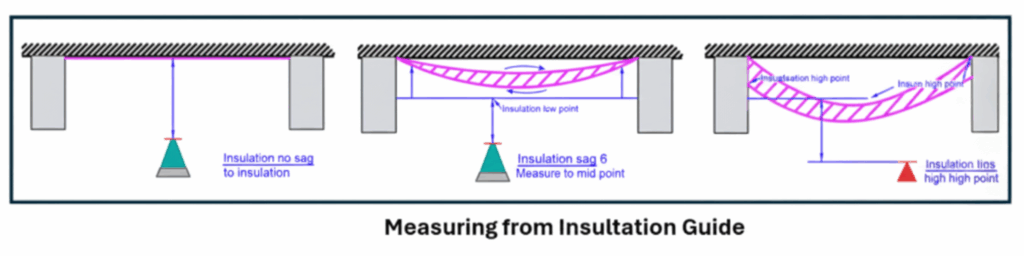

Insulation on the underside of the ceiling or roof structure. Insulation is commonly added on the structure’s underside, and the depth of such insulation varies depending on the exterior climate. Not only can the existence of this material influence the sprinkler’s placement, but the manner in which it is installed can also play a role if the insulation “sags” away from the structure. To solve this problem, Section 9.5.4.1.3 states that the deflector distance must be calculated from the underside of the insulation, unless the insulation sags. If the sag is six inches or less, the measurement must be taken at the centre of the sag. If the sag reaches six inches, we take measurements from the highest point. The standard also requires that if the insulation is not “batt” type, it must withstand 3 lb./ft2 of “uplift” force – this is to ensure that during a fire event, the energy from the fire plume does not “lift” the insulation layer up, increasing the deflector distance and potentially delaying activation.

To avoid problems during field inspections, it is usually a good idea to look over the architectural drawings and discuss the building’s thermal “shell” with the project design team.

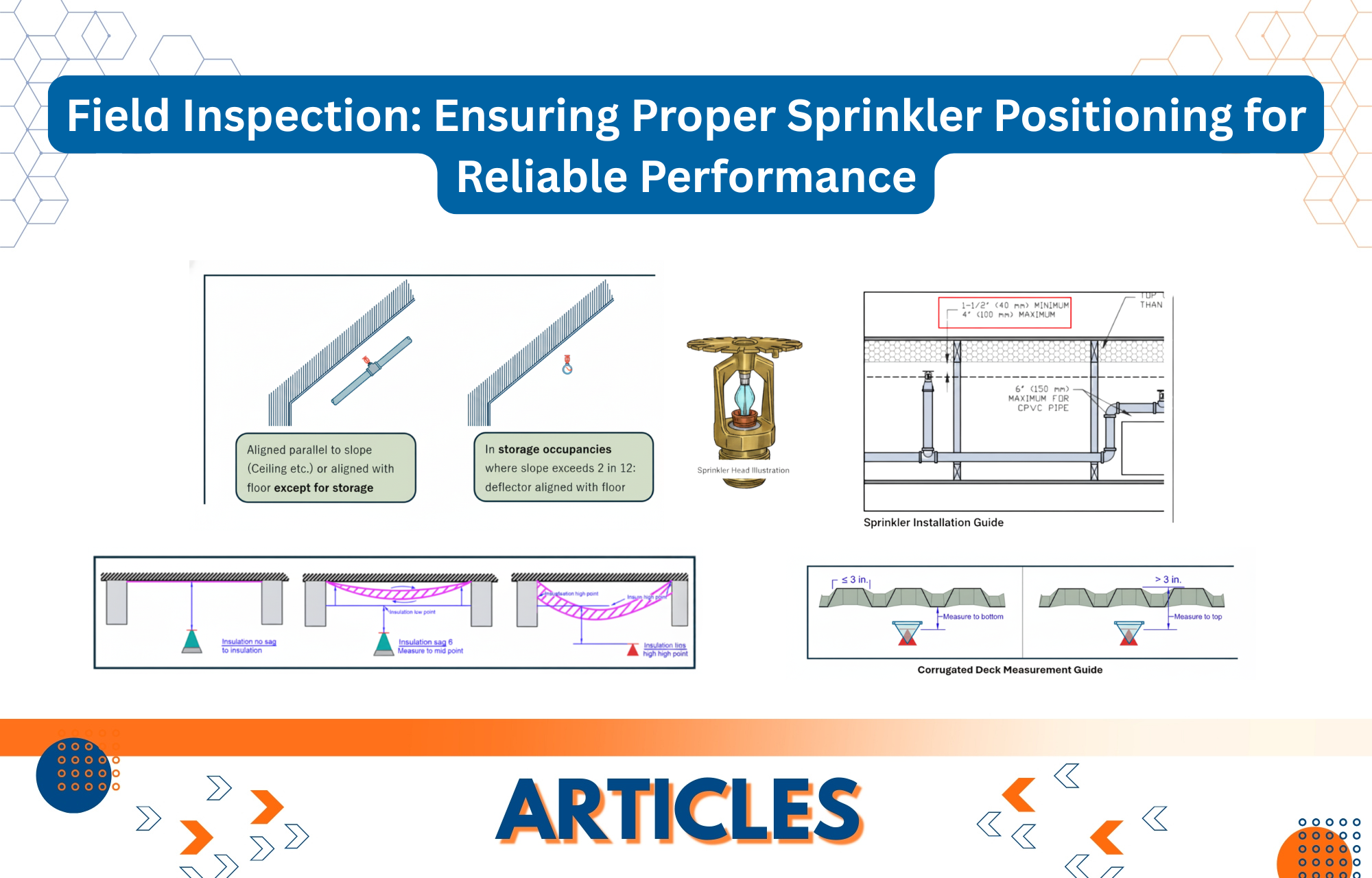

Deflector orientation. The angle of the sprinkler deflector and the pitch of the roof or ceiling are essential factors in appropriate positioning. Based on the findings of testing for ESFR storage applications in sloped ceilings, the 2025 edition of NFPA 13 now requires deflectors to be parallel with the floor in all storage applications where the ceiling slope exceeds 2:12, and allows for flexibility in all non-storage applications to orient the deflector with the ceiling slope or parallel to the floor. In previous editions, the deflector was typically installed parallel to the pitch of the ceiling whenever the slope surpassed 2:12.

Positioning Special Sprinklers

With all of the crucial information provided by NFPA 13 for sprinkler installation and positioning, there are a number of circumstances in which “special sprinklers” are either chosen or mandated to be installed to protect unique risks or structural characteristics. For example, Section 9.3.2 specifies that sprinklers protecting horizontal combustible concealed spaces (interstitial spaces) be included for this application. Another example is the use of special “attic” sprinklers, which are an optional design technique for protecting sloped flammable concealed attics that are not designed for occupation or storage.

In both cases, it is vital to follow the manufacturer’s stated instructions throughout design and installation. Many of the rules governing these sprinklers are not mentioned in NFPA 13, as they pertain to the listing of the unique sprinkler. NFPA 13, Section 9.4.1.1, clearly states that installation must be done in line with the sprinkler’s listing. To avoid problems during a field inspection, become acquainted with the specifics of the manufacturer’s requirements, where applicable, and keep in mind that the technical services desks of these manufacturers are a wealth of knowledge and experience – make use of them when you require additional assistance.

The following are instances of sprinkler location and deflector distance requirements that differ significantly from the prescriptive criteria of NFPA 13.

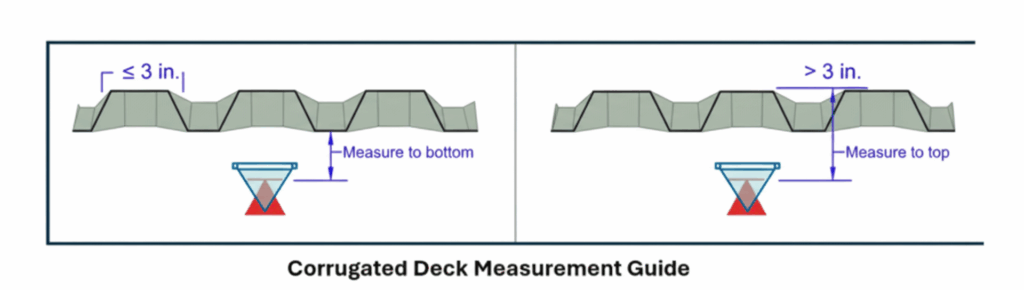

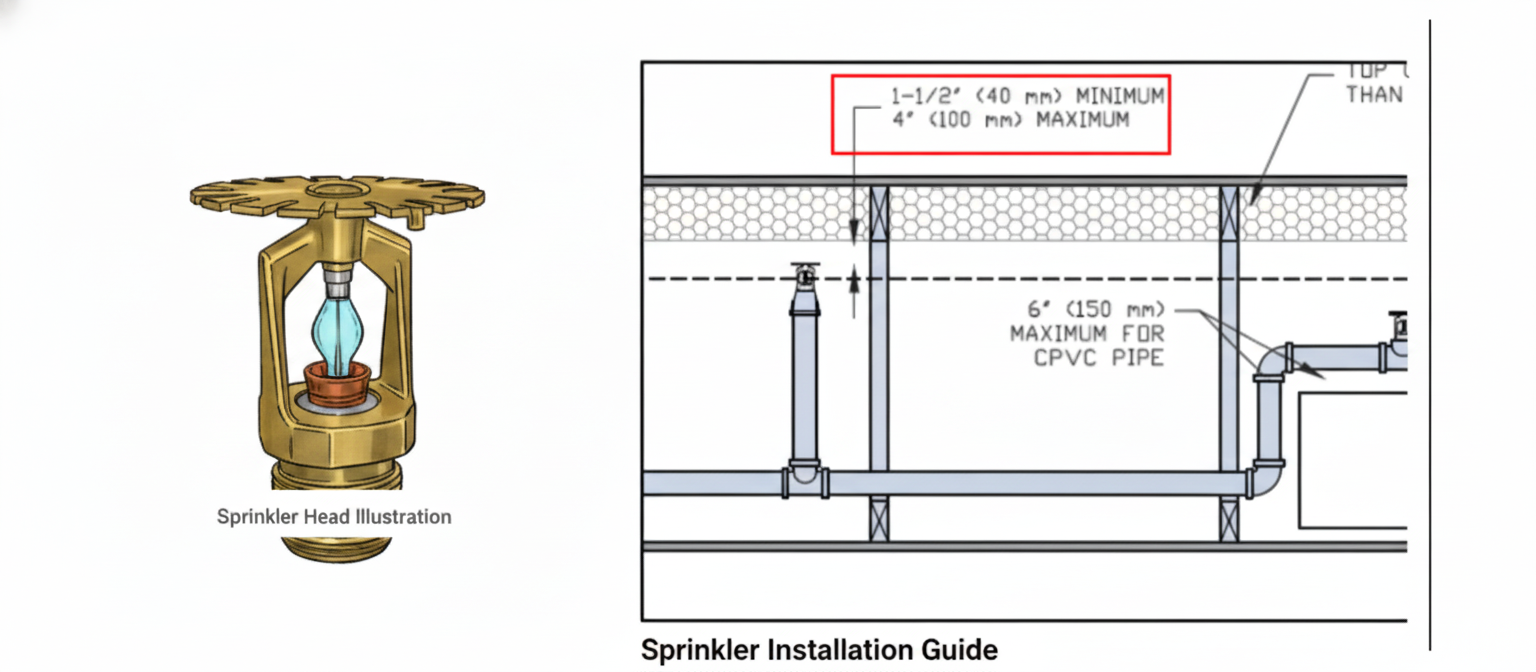

Sprinklers for combustible spaces (interstitial). While different manufacturers provide their own “version” of these unique sprinklers, the majority of the regulations for deflector positioning and other requirements are generally consistent across manufacturers. In the example below from a manufacturer’s cut sheet, the diagram shows a minimum 1.5″ and maximum 4″ deflector distance for one specific application.

Attic sprinklers. Deflector distances, for example, may differ between manufacturers, so be sure to follow the published instructions from the manufacturer chosen for the system design. Each diagram shows a slightly different deflector distance range for similar applications.

Coordinating Design and Installation for Successful Field Inspections

Construction can be fast-paced and sometimes unpredictable. Unexpected modifications are common, with building design and construction elements being amended or even overlooked by one side or another during the structure’s completion process. Adjusting or moving sprinklers, for example, can be costly and cause project delays that no one wants. Here are a few variables that may influence sprinkler positioning before, or even after, a field inspection.

Insulation. In both of the images below, insulation has been added. One sprinkler is visibly “buried” and only visible because the photographer removed some of the material to reveal it. In the other case, the sprinkler deflector distance looks to be “under” the insulation, but it should be examined more closely to assure compliance and proper operation because it appears to be close to it. If the implications are not considered during design and installation, they might be disruptive.

Spray-on fireproofing. Structural members are occasionally given further protection, such as spray-on fireproofing compounds. If neglected or added to the design later in the project, it may have an impact on whether the structural member is adequately “open,” leading in an impact on sprinkler positioning and a potential problem during field inspections. In Section 3.3.4.6.2, NFPA 13 defines “unobstructed construction” as “at least 70% open…”. In many cases, the use of this material may alter how ‘open’ the structural member is.

Structural modifications, soffits, and more. Typically, there are long periods of time between the rough inspection and the final walkthrough. Occasionally, materials, decorative components, architectural features, and other aspects are applied late in the life of a project, presenting vulnerabilities for field inspection. If not considered during design and installation, these can have an impact on sprinkler placement. With the rapid pace of development, staying on top of these issues is more said than done, but strong communication between parties can go a long way.

Closing Thoughts

Putting sprinklers in the appropriate area is not only a code requirement, but it is also a crucial part of ensuring they work. People who operate in the field, such designers, installers, and inspectors, may make sure that systems work when they need to by always following the installation regulations in NFPA 13 and the directions from each manufacturer. Careful field inspection and correct placement not only make things safer and more compliant, but they also help projects go more easily and make it easier for everyone involved in fire prevention to work together.