Rotaflow Safety Culture

Every project at Rotaflow is focused on safety and compliance. Maintaining a positive safety culture is fundamental regardless of fire protection, utility services, or specific hazard solutions. Our staff is dedicated to adhering to strict policies and maintaining industry standards to guarantee the public’s, clients’, and workers’ well-being.

Safety First is one of our core values.

System of Integrated Safety Management

Rotaflow functions under a completely integrated safety management system designed to detect, track, and lower risks in all sectors of our activity. Consistent practices across sites made feasible by this technology guarantee regulatory compliance, incident avoidance, and continuous improvement by way of homogeneous policies.

Digital technologies track and maintain accuracy all through safety-related operations, including field assessments, equipment inspections, and training completion. Our Safe Workhub database guarantees traceability and responsibility by storing all safety documentation, including risk assessments, daily reports, and inspection logs.

Proactive Safety Measures

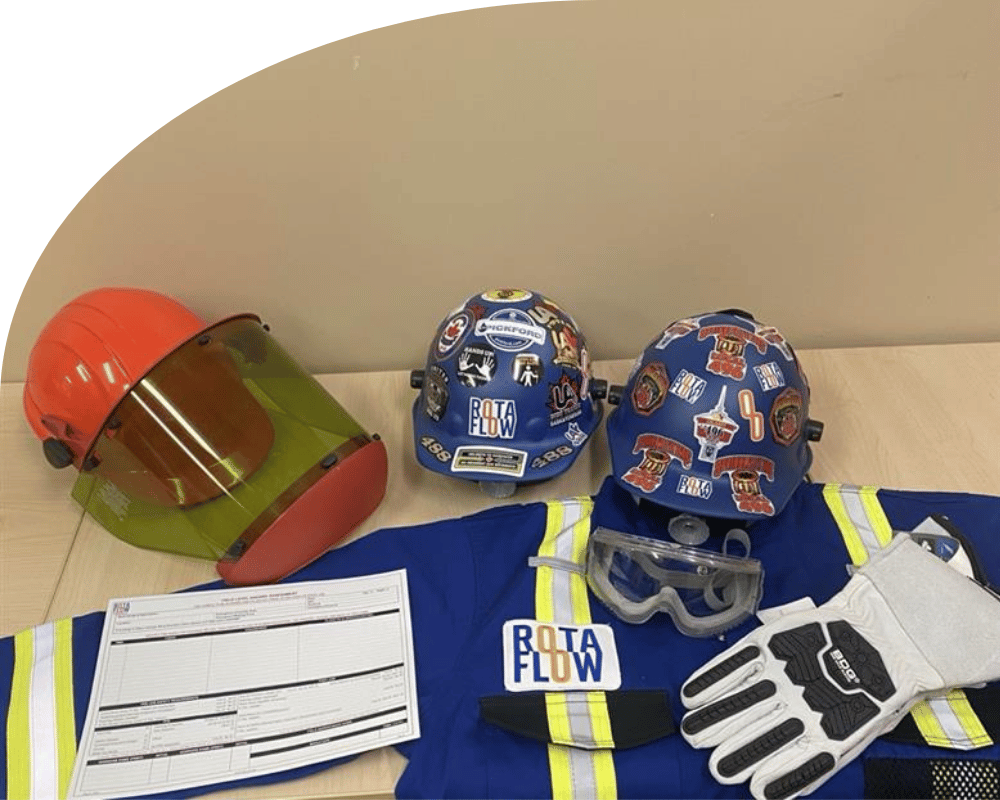

Our approach to safety starts before work begins. New hire onboarding and site-specific training are mandatory for all personnel before arriving on-site. This procedure ensures that every individual is familiar with the site layout, potential hazards, emergency procedures, and personal protective equipment (PPE) requirements.

Every shift begins with a daily toolbox meeting where planned tasks, potential risks, and safety reminders are discussed. This open communication encourages everyone to speak up about concerns and take ownership of safety practices.

A Field Level Hazard Assessment (FLHA) is conducted by field personnel before starting any task. This assessment identifies possible hazards and outlines control measures to reduce risk. It is a key part of our culture of safety and helps prevent incidents in dynamic work environments.

Equipment and Vehicle Safety

All tools and equipment used in our operations go through rigorous pre-use and post-use inspections. If any defects are found, the tools are tagged out of service and either repaired and certified or replaced. Our teams understand that proper tool maintenance is essential for both efficiency and safety.

Before using any vehicle, a full vehicle inspection is conducted. These checks are documented in our system before and after each trip. This process ensures the safe operation of vehicles and reduces the risk of mechanical failure on-site.

Regular Site Inspections and Walkdowns

Site walkdowns and inspections are conducted regularly to identify hazards, observe work practices, and ensure compliance with safety protocols. These inspections are repeated whenever there is a change in the job scope or work environment. Any issues identified are addressed immediately, and follow-ups are tracked within our safety system.

When materials arrive on site, they are safely offloaded in designated areas and inspected to confirm they are in proper working condition. Safe handling and storage of materials help reduce potential safety risks on active job sites.

Proper Use of PPE and Spotters

Every task is assessed for site-specific PPE requirements. If specialised equipment or clothing is needed, training is provided to ensure workers use it correctly. Whether it’s respiratory protection, eye protection, or flame-resistant clothing, our team is trained to comply with the necessary standards.

When operating heavy machinery or moving equipment, a spotter is mandatory to guide operations and prevent collisions. We also follow all site-specific traffic rules, ensuring safe movement in and around work areas.

End-of-Day Reporting and Continuous Improvement

At the end of each workday, our crews submit activity reports, documenting completed tasks, safety issues, and any incidents or near misses. These reports are stored in our Workhub database and reviewed regularly to look for trends, improve procedures, and prevent recurrence.

When an incident does occur, Rotaflow Fire and Utility follows a clear and transparent process. We investigate what happened, determine the root cause, and implement corrective actions to prevent it from happening again. These lessons are shared among teams to enhance safety across all sites.

Commitment to Compliance and Safety

Rotaflow is fully committed to meeting and exceeding all occupational health and safety requirements and fire protection compliance standards. Our safety practices aim to foster a safe and productive environment, ensuring everyone returns home safely.

Whether it’s installing fire protection systems, utility infrastructure, or specialised hazard mitigation, Rotaflow ensures every task is completed with a focus on safety, professionalism, and full compliance.

Safety Standards & Affiliations

Let's work together to tackle your next big challenge.

Contact Us

Please note that all forms and emails will be replied to within 24 hours. For immediate assistance, call 780-469-1220.