Understanding and Applying NFPA 13 Obstruction Rules: Essential Knowledge for Fire Sprinkler Design

Introduction

Real-world installation issues for NFPA 13 often make it difficult for layout technicians, AHJs, and installers to decide whether an obstruction regulation applies—or how to apply it properly. Understanding this continuous difficulty, the National Fire Sprinkler Association (NFSA) is working with MeyerFire to provide a specific tool to help to clarify these guidelines. With useful advice that will enable industry professionals to confidently analyse and implement the regulations to guarantee code-compliant and effective fire prevention solutions, it describes the basic obstruction principles in NFPA 13.

Obstructions

A successful layout technician must be able to deal with fire sprinkler obstructions. The various real-world obstructions encountered can be difficult to manage and determine if the appropriate NFPA 13 obstruction rule applies. As a result, obstructions are consistently one of the top queries submitted to NFSA’s Experts of the Day program.

As this problem continues to create questions in our business, the NFSA, in collaboration with MeyerFire, is working on a book dedicated to demystifying obstructions in fire sprinkler installation and design.

Obstructions Overview

Dealing with sprinkler obstructions is a procedure that should be understood by all parties involved. Before delving into the precise obstruction rules, it is important to grasp the fundamental requirements, or performance criteria, on which the obstruction rules are founded. Section 9.5.5.1 states the following objectives:

“Sprinklers shall be arranged in accordance with 9.5.5.2 and 9.5.5.3 to minimise obstructions to discharge, or supplemental sprinklers shall be provided to ensure adequate coverage of the hazard.”

This section states, in English, that sprinklers must be positioned in such a way that any impact on sprinkler discharge is minimal. This part goes on to say that if the impact of obstacles cannot be successfully mitigated by using the obstruction regulations, then extra sprinklers must be installed to compensate for the effect of the obstructions.

Section 9.5.5.1’s order implies that there are two methods of dealing with obstructions, with the recommended method being:

Sprinklers are configured so that any impact on the sprinkler discharge is minimised.

If the first charge is not possible (due to the obstruction laws), the backup position is simply:

Add more sprinklers to compensate for obstructions.

This second option has the potential to raise the water consumption and cost of sprinkler systems, making it the second alternative for dealing with obstacles.

Obstruction Zones

Sprinkler obstructions are classified into two “Zones of Obstructions” with distinct rules:

- Obstructions to Sprinkler Discharge Pattern Development, Section 9.5.5.2:

According to this section, any obstruction located within 18 inches (36 inches for ESFR and CMSA) of the sprinkler deflector must be addressed by the appropriate obstruction rule found in the chapter for the sprinkler in question. An impediment within 18 inches of a sprinkler’s deflector disrupts the sprinkler’s ability to create a complete spray pattern. The first 18 inches allow the water to create a spray pattern.

This is where the well-known obstruction rules, such as the “beam rule” and the “partition rule,” are enforced.

- Obstructions that prevent sprinkler discharge from reaching the hazard, Section 9.5.5.3

This section indicates that if the impediments are more than 18 inches below the sprinkler deflector, the rules of 9.5.5.3 must be observed. An impediment more than 18 inches below a sprinkler’s deflector prevents water from reaching the floor or the burning fuel source. Burning fuel that is’shielded’ from water spray can continue to grow, posing an increased risk to the building and its people. Overall, fire sprinkler systems require water to reach or surround the burning hazard in order to successfully suppress the fire.

In general, if the barrier is more than 4 feet broad and is fixed in situ, extra sprinklers must be placed to defend against a potential fire under it. This rule is often referred to as the “duct rule.”

Obstruction Definitions

Before using the numerous obstacle laws, it is necessary to understand the concept of obstructions in various forms, as well as associated concepts. An obstacle is commonly defined as an object at or below the level of the sprinkler deflector that stops the discharge pattern from fully developing or the water flow from reaching the fire.

However, impediments can take many forms, and understanding the many types and forms of obstructions is critical to coping with them successfully. The most effective approach to accomplish this is to reread the definitions in Chapter 3.

Continuous Obstruction

An impediment alters the discharge pattern of two or more sprinklers.

Non-continuous obstruction

An impediment that alters the discharge pattern of a single sprinkler.

Solid obstruction

An obstacle without apertures that does not exceed 30% of the object’s footprint.

Non-solid obstruction

An obstacle in which apertures account for 30% or more of the object’s footprint (new in 2025). For example, consider a cable tray.

Non-Flat Obstruction

An obstruction occurs when the bottom is not in the same plane, preventing it from gathering heat. (New for 2025) Example: a round duct.

Fixed Obstruction

A permanent or non-movable obstacle.

Obstacle In Vertical Orientation

An obstacle that runs in an upward and downward manner. Consider the following example: Column.

Obstacle in Horizontal Orientation

An impediment that runs parallel to the ground (left or right). Examples include ducts and pipelines.

General Obstruction Rules

To reduce the impact of obstructions, NFPA 13 has established a set of obstruction guidelines. While these regulations are particular to the type of sprinkler used, the obstruction rules for standard spray sprinklers in Chapter 10 can be summarized as follows:

“Beam Rule”: This rule is used when obstructions are close to the ceiling and water cannot get over them, as well as when obstructions are continuous and water cannot reach the sides of the obstruction. It is used to assess whether enough water can get beneath the obstruction. Section 10.2.7.2 of NFPA 13.

“Sprinklers on Opposite Sides of Obstructions Rule”: If an impediment is less than 4 feet wide, sprinklers can be installed on either side as long as they are not more than ½ the permissible distance between sprinklers, which is normally 7 ½ feet apart.

“Soffit Rule #1”: Where an obstruction is against a wall, such as a soffit, and is not more than 30 inches wide, permissible sprinkler locations can be found using the following equation:

![]()

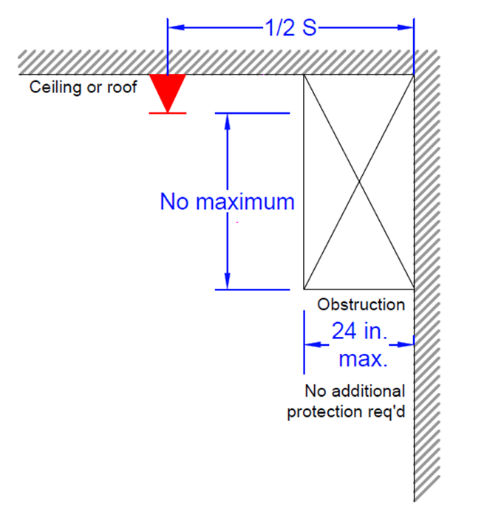

“Soffit Rule #2” : It states that if an impediment, such as a soffit, is less than 24 inches wide and less than ½ of the permissible distance from the wall, no additional sprinkler is needed.

The “Three-Times Rule”: It evaluates if enough water from a conventional spray sprinkler can reach both sides of a barrier. The “three times rule” states that sprinklers should be three times the maximum dimension of the potential blockage away.

It should also be noted that for horizontally orientated impediments, the maximum clear distance from a sprinkler is 24 inches. This maximum clear distance does not apply to impediments in the vertical plane.

It should be noted that with Extended Coverage and Residential Sprinklers, the “Three-Times Rule” is changed to the “Four-Times Rule.”

“Partition Rule” : Two special obstruction regulations apply to suspended or floor-mounted barriers that do not reach to the ceiling, such as half walls, cubicle walls, and so on. The first is limited to light danger occupancies and can be regarded as the beam rule reversed.

In the 2022 edition, a new partition rule for ordinary hazard occupancies was devised, with two variations:

In the 2022 edition, a new partition rule for ordinary hazard occupancies was devised, with two variations:

“Wide Obstruction Rule”: As previously indicated, sprinklers should be installed under fixed obstructions that are more than 4 feet broad. The rules from the 2022 edition can be summarised with the following figure:

“Wide Obstruction Rule”: As previously indicated, sprinklers should be installed under fixed obstructions that are more than 4 feet broad. The rules from the 2022 edition can be summarised with the following figure:

Applying the Obstruction Rules

Now that the main concepts of the NFPA 13 obstruction rules have been summarised, the next step is to apply them correctly. Applying these criteria properly requires a technique, similar to the designing of a sprinkler system. The following is a summary of seven actions to guarantee that obstructions are dealt with correctly:

Step 1: Evaluate the Space. To detect potential impediments, it is vital to evaluate the blueprints, which include:

Architectural plans: The reflected ceiling designs highlight potential impediments near the ceiling.

Structural plans: It will highlight which structural parts may hinder the sprinklers’ spray patterns.

Mechanical plans: It will highlight whether significant mechanical systems (such as HVAC ducts) may hinder the sprinkler spray pattern.

Electrical Plans: The lighting plans will specify which light fixtures may block the sprinkler’s spray pattern.

Plumbing plans: It will show which piping systems may hinder the sprinklers’ spray patterns.

Speciality Plans: Indicate which unique systems may hinder the sprinkler spray pattern.

Step 2: Are Sprinklers Required? As stated in portion 4.1.1, NFPA 13 mandates sprinklers be installed in all locations unless a specific portion of the standard allows for their exclusion. If a specific location does not require sprinklers, there is no need to consider potential obstructions.

Step 3: Determine Occupancy Classification: The occupancy classification is required to determine sprinkler spacing, which in turn affects obstruction rules.

Step 4: Obstructed vs. Unobstructed Constructions The deflector distance below a ceiling is influenced by whether it is obstructed or unobstructed. This, in turn, will affect the obstruction rules.

Step 5 – Combustible vs Noncombustible: Whether the construction is combustible or noncombustible can influence sprinkler spacing (Sidewall Sprinklers). This may affect allowed spacing, and hence the obstruction rules.

Step 6: Select the Sprinkler Type. Obstruction restrictions vary depending on the type of sprinkler. It is critical that the correct rules are followed.

Step 7: Position the sprinklers: The spacing, deflector position, and pattern of the sprinklers will influence which elements are considered barriers.

Step 8: Universal Obstruction Rules: Chapter 9 of NFPA 13 contains rules that apply to all sprinkler types. These regulations are extended in the chapters relating to the sprinkler type chosen. This flow chart will provide a general summary of how to apply the following general rules:

Step 9: Sprinkler Specific Rules: When dealing with fire sprinkler obstructions, it is critical to first determine the sprinkler type. Obstruction standards vary depending on the sprinkler type (standard, extended coverage, residential, CMSA, or ESFR). For example, ordinary spray sprinklers frequently target obstructions within 18 inches of the deflector, but CMSA models increase the focus to 36 inches. Recognising these distinctions early on avoids confusion and allows you to apply the appropriate guidelines to each case. The flowchart below summarises how to implement the Chapter 10 obstruction regulations for Standard Spray Pendent and Upright Sprinklers.

Summary

Reliable fire sprinkler performance and code compliance depend on a knowledge of and application of NFPA 13’s obstruction rules. This guide helps experts to spot problems early in the design process by precisely separating the two kinds of obstacle zones and specifying important definitions—such as continuous, fixed, and non-solid obstructions. While providing a step-by-step approach for correct application, it also breaks out the basic guidelines for typical spray sprinklers, including the beam rule, soffit regulations, and three-times rule. Even in the most difficult architectural settings, technicians, designers, and AHJs can make sure fire sprinklers are positioned for maximum effectiveness, safety, and efficiency.

Courtesy:Roland Asp, NFSA Manager of Codes and Standards.